Study of Chrome Ore Magnetic Separation and Gravity Separation Process

The chrome ore beneficiation processes include gravity separation, flotation, magnetoelectric separation and chemical beneficiation, etc. Because of the chrome ore composition that composed of one or more silicate, and the density difference between the chrome and silicate, the research both in home and aboard about chrome beneficiation process mainly focuses on the gravity separation process. However, using a single gravity separation process can improve the chrome grade, but fail to recover it effectively. In this paper, try to find a better way by using a combined beneficiation process of gravity and magnetic separation.

1 Chrome ore properties

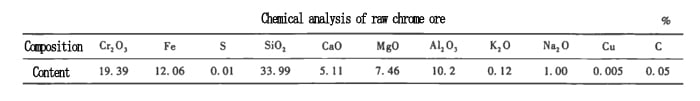

【Chemical analysis】

The raw chrome ore is the tailings after floating separation of platinum and palladium, and the grade of Cr2O3 is relatively high.

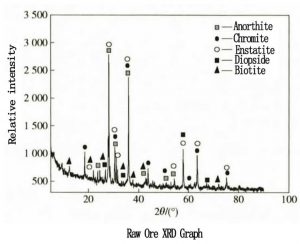

【X-ray diffraction analysis】

The main mineral ores in the chrome sample are chromite, enstatite, anorthite, hopfnerite, diopside, albite, biotite, etc.

【Physical analysis】

The metallic minerals in the chrome samples are mainly chromite, the gangue minerals are mostly enstatite and anorthite, followed by tremolite, diopside, quartz and albite, and a small amount of biotite, serpentine and chlorite, trace amounts of calcite, chalcopyrite, sphene, etc.

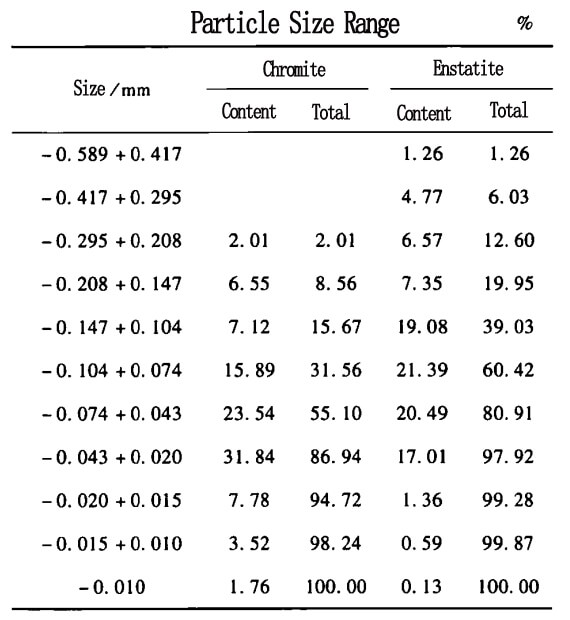

Cr2O3 is found in the form of individual minerals, mostly in chromite, few in enstatite. Therefore, chromite is the target minerals to be recovered in this experiment. The following is a systematic grain size grade of chromite and enstatite.

As shown in the table above, the chromite material particle mainly of middle-fine of finesse, cover in the range of 0.02-0.104mm. In which, the particle of +0.074mm account for 31.56%, -0.043mm account for 44.9%, -0.010mm only account for 1.76%. Concentrated distribution same as the chromite, the particle of enstatite mainly in 0.020mm-0.147mm, -0.010mm only account for 0.13%.

2 Experimental scheme

The dissociation degree of chromite monomer in the sample is 95.11%, the magnetism can be used to separate the chromite from the nonmagnetic ores. The gangue minerals, such as enstatite, tremolite, diopside, biotite, also have weak magnetism, affect the grade of magnetic concentrate. It is better to separate it by using gravity separation.

In this experimental, we adopt a strong magnetic process, roughing- concentration- scavenging, to remove the impurity preliminary, then to separate the chromite from nonmagnetic ores. at next, using gravity separation process to refine the chromite concentrate and scavenging tailings, meanwhile, improve the grade and recovery rate.

Chrome process equipment is wet type strong magnetic separator, and spiral chute (chrome spiral plant) of gravity separator.

3 Experimental results and discussion

3.1 Chrome magnetic separation process

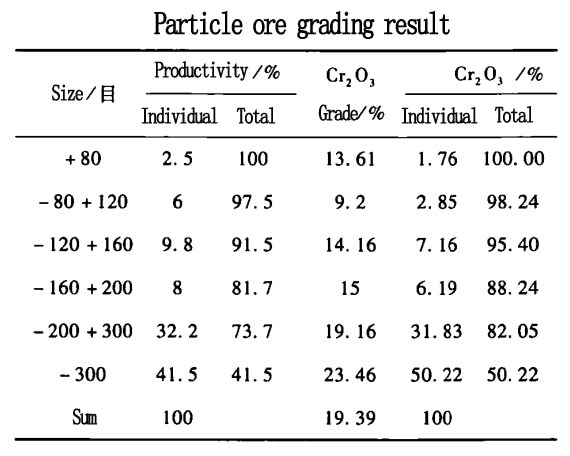

The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral. The dissociation degree of ferrochromium ore is low, and it has a weak magnetic property. First of all, magnetic separation processing to separate chromite. Besides, the grain size is fine, so there is no need for grinding, the grading result shown in the below.

Raw ore process flow: roughing- concentration- scavenging. the Cr2O3 mainly in the fine particle ore, in order to ensure the grade and recovery rate, take the roughing experimental under the high gradient separation condition, results as follows.

The results of this study show that, after the first rough separation, the grade of chromite concentrate Cr2O3 is 32.06%(13% higher than the grade of raw ore), the productivity of that is 48.88%, and the recovery rate of that is 83.04%. In order to know the Cr2O3 distribution among the concentration and tailings, make a grade sieving in the roughing concentration and tailings respectively.

As can be seen from the above table, in the concentration, the Cr2O3 mainly in the fine particle grade; in the tailings, the Cr2O3 distribute evenly. strong magnetic separation can recover the valuable minerals, but don’t increase the chromite mineral grade to the metallurgical grade, that is, the Cr2O3 higher than 38%.

To carry on the advanced concentration experimental to the roughing separated concentrate ore, and scavenging experimental to the roughing separated tailings ore for the sake of improving Cr2O3 grade.

After the advanced concentrate process, the grade of concentrate Cr2O3 is 38.5%, reach the smelting grade, and that of tailings is 24.28%. After the scavenging process, the grade of concentrate Cr2O3 of roughing tailings is 15.07%, that of tailings is 2.4%. It turns out that the roughing process tailings and scavenging process concentrate have recovery value.

3.2 Gravity separation process

The density of chromite ore is slightly higher than that of its other magnetic gangue ore. Therefore, the separation of ferrochromium from other minerals can be realized by gravity separation.

Use spiral chute to separate the concentrate process tailings and the scavenging process concentrate respectively. As shown in the gravity beneficiation process result, both of the grade of concentrate process tailings and scavenging process concentrate higher than 40%, the productivity of that is up to 70%. In conclusion, gravity separation technology can purify the chromite significantly.

4 Conclusion

As for the chrome beneficiation processes, the single gravity separation process can obtain the qualified grade but does not ensure the productivity and recovery rate. The combination of magnetic process and gravity separation can ensure all indexes of grade, productivity and recovery rate.

JXSC as a service provider of mineral extraction since 1985, all the time focus on solving trouble during the ore mining process, and supplying mineral processing solutions and equipment for various of metals including chrome, silver, gold, titanium, zinc, tin, lead, and so on. As for chrome mining, we have built close relationships with many chrome ore mines in South Africa. Visiting our customers of Chrome wash plants South Africa is a good idea for you to know us deeply from product quality and service. Contact engineer for details of chrome ore processing plant.