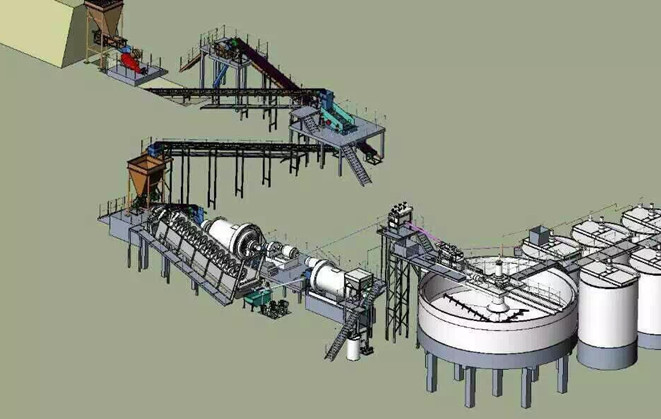

Carbon in Pulp

Gold Carbon-in-pulp (CIP), Gold CIP Production Line

Gold Carbon-in-pulp (CIP) production line is an extraction technique for recovery of gold which has been liberated into a cyanide solution as part of the gold cyanidation process.

Carbon in pulp process

Gold Carbon-in-pulp (CIP) production is the sequential leach, then absorption of gold from ore. During the CIP stage, pulp flows through several agitated tanks where sodium cyanide and oxygen have been added to dissolve gold into solution.

CIP process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content. It is unsuitable for the gold ore with high grade silver as well. Generally, the proportion of gold and silver should not exceed 1:5. The best conditions for CIP process in China: PH=10-12, sodium cyanide concentration is not less than 0.015%, the particle size of activated carbon is 1.0-3.35mm, the best choice of carbon is coconut shell activated carbon, and the slurry concentration is 40-45%.

- Crushing and Screening

- Grinding and Classification

- Thickening

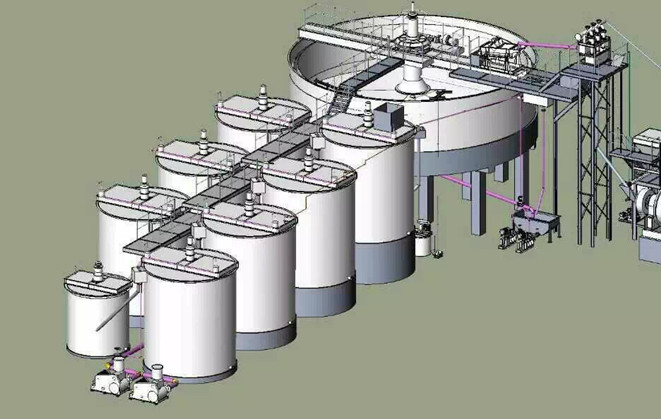

- Leaching

- Adsorption

- Desorption of Gold-loaded Carbon and Electro-deposition

There are several desorption methods. In China, the general application methods are Zadra desorption method, high temperature, and high-pressure desorption method (hereinafter referred to as HTHP method) and integral pressure desorption method (hereinafter referred to as IP method).

300T/P CIP Equipment list

| No. | Product name | Model | Qty | Motor Power(kw) |

| 1 | Trough feeder | 980*1240 | 1 | 7.5 |

| 2 | Jaw Crusher | 400*600 | 1 | 30 |

| 3 | Jaw Crusher | 250*1000 | 1 | 30 |

| 4 | Vibrating screen | 1500*3000 | 1 | 7.5 |

| 5 | Swing feeder | 600*600 | 1 | 1.5 |

| 6 | Ball mill | 2100*3600 | 1 | 210 |

| 7 | Ball mill | 1500*4500 | 1 | 110 |

| 8 | Spiral classifier | Φ2000 | 1 | 11 |

| 9 | Mixing tank | Φ2000 | 1 | 5.5 |

| 10 | Mixing tank | Φ1000 | 2 | 1.5 |

| 11 | Mixing tank | Φ1000*1500 | 1 | 3 |

| 12 | Hydrocylone | Φ250 | 2 | |

| 13 | Thickener | Φ12000 | 1 | 3 |

| 14 | Leaching agitaion tank | Φ3500*4000 | 9 | 4 |

| 15 | Linear Vibrating Screen | 400*1600 | 3 | 0.25 |

| 16 | Lifting carbon machine | 7 | ||

| 17 | Carbon Screen | 7 | 0.25 | |

| 18 | Slurry pump | 3/4 | 6 | 22 |

| 19 | acid pump | 1.5 inch | 1 | 3 |

| 20 | Roots blower | 200 | 1 | 45 |

| 21 | Desorption electrolysis system | 300kg | 1 | 30 |