Zircon Mining Process

What is Zircon

Zircon is ubiquitous in the crust of Earth. It occurs as a common accessory mineral in igneous rocks (as primary crystallization products), in metamorphic rocks and as detrital grains in sedimentary rocks. Large zircon crystals are rare. Their average size in granite rocks is about 0.1–0.3 mm, but they can also grow to sizes of several centimeters, especially in mafic pegmatites and carbonatites. Zircon is also very resistant to heat and corrosion.

Because of their uranium and thorium content, some zircons undergo metamictization. Connected to internal radiation damage, these processes partially disrupt the crystal structure and partly explain the highly variable properties of zircon. As zircon becomes more and more modified by internal radiation damage, the density decreases, the crystal structure is compromised, and the color changes.

Zircon Mining

Mining of mineral sands can be by both dry mining and wet (dredge) mining methods. In some countries, mineral sands products, principally titanium minerals, are also recovered from hard rock mining methods.

Dry mining is suitable where deposits are shallow, contain hard bands of rock, or are in a series of unconnected ore bodies.

Barytes Uses

Zircon is mainly consumed as an opacifier, and has been known to be used in the decorative ceramics industry. It is also the principal precursor not only to metallic zirconium, although this application is small, but also to all compounds of zirconium including zirconium dioxide (ZrO2), one of the most refractory materials known.

Other applications include use in refractories and foundry casting and a growing array of specialty applications as zirconia and zirconium chemicals, including in nuclear fuel rods, catalytic fuel converters and in water and air purification systems.

Zircon Mining Methods

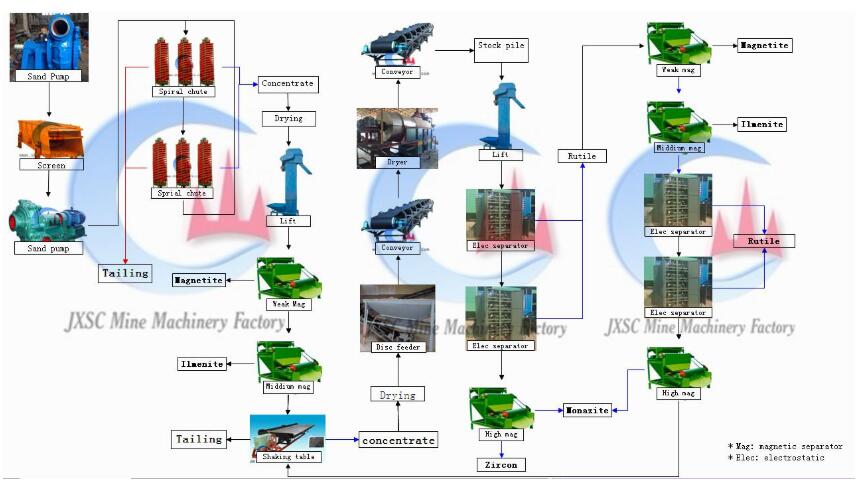

Gravity separation:

Zircon occurs in ilmenite and often accompanied by hematite, chromite and garnet and other heavy minerals. Therefore, in the initial stage of zircon enrichment, gravity separation is often used, such as shaking table to separate heavy minerals from gangue(quartz, feldspar, biotite)and other heavy minerals.

Flotation:

commonly used collectors are fatty acids(oleic acid, sodium oleate), the slurry regulator is sodium carbonate, the inhibitor is sodium silicate, the activator is sodium sulfide and heavy metal salts(zirconium chloride, ferric chloride). Oxalic acid is also used to adjust the pulp to acid and flotation with amine collectors.

Electrostatic separation:

The conductive minerals, such as ilmenite, hematite, chromite, cassiterite and rutile, are separated from the non-conductive minerals such as zircon, monazite, garnet and apatite by using the difference of conductivity of minerals. Before deselect, desliming, drying and dosing should be done.

Magnetic separation:

Heavy minerals in the magnetic minerals are ilmenite, hematite, chromite, garnet, biotite, monazite and so on. Zircon is a non-magnetic mineral or a weakly magnetic mineral. Magnetic separation is divided into two types: dry type and wet type. Dry magnetic separation must be preheated before drying and grading. The wet magnetic separator has a wide particle size and a lower particle size of 20um. Therefore, when the zircon particle size is fine, the wet magnetic separator is more suitable.

Because there are many associated minerals in zircon sand, it is necessary to combine gravity separation, magnetic separation, flotation and electrostatic separation.

The zircon sand concentrator is often divided into two parts: wet treatment and dry treatment. In the wet treatment stage, gangue minerals such as quartz, feldspar and mica are removed by gravity separation equipment such as cone concentrator, spiral concentrator, shaker or jig. The heavy minerals(crude concentrate)obtained are further separated by 2-4 stages of concentrating to remove the remaining light minerals, and then concentrated, dehydrated, dried, cooled and sent to dry treatment stage for further separation. Dry processing section is generally made up of weak magnetic separation, high-intensity magnetic separation and electrostatic separation.

The aim is to recover magnetite, ilmenite, rutile and monazite which are associated with zircon. Magnetite can be recovered by weak magnetic separation, ilmenite and garnet can be recovered by strong magnetic separation, and monazite, rutile and zircon can be separated by high voltage electrostatic separator.