Gravity separation is an effective method for separating minerals of significantly different densities. It is an industrial method of separating two components from a suspension or any other homogeneous mixture where separating the components with gravity is sufficiently practical. It is a unit process in which gravity removes settleable solids and associated pollutants, floatables and dispersed petroleum products. The effectiveness of separation is also dependent on particle size, not just density. In some cases, separation may be effective down to 50µm. There are two opposing forces that are always present in gravity separation are Gravity ( i.e. dependent on specific gravity) and Resistance to movement. For effective separation, there must be a marked difference in densities. The concentration criteria will be given as an idea as to the effectiveness of the separation. Concentration criterion = (DH – DF) / (DL – DF). Where DH is the density of the heavy material, DF is the density of the fluid and DL is the density of the light material. When the concentration is more than ±2.5, gravity separation should relatively easy.

Gravity separation is an effective method for separating minerals of significantly different densities. It is an industrial method of separating two components from a suspension or any other homogeneous mixture where separating the components with gravity is sufficiently practical. It is a unit process in which gravity removes settleable solids and associated pollutants, floatables and dispersed petroleum products. The effectiveness of separation is also dependent on particle size, not just density. In some cases, separation may be effective down to 50µm. There are two opposing forces that are always present in gravity separation are Gravity ( i.e. dependent on specific gravity) and Resistance to movement. For effective separation, there must be a marked difference in densities. The concentration criteria will be given as an idea as to the effectiveness of the separation. Concentration criterion = (DH – DF) / (DL – DF). Where DH is the density of the heavy material, DF is the density of the fluid and DL is the density of the light material. When the concentration is more than ±2.5, gravity separation should relatively easy.

1 Description of gravity separation

Gravity beneficiation is a method of sorting ore in a certain fluid medium according to the difference in mineral density. The gravity separation process is carried out in a fluid medium, usually water, and sometimes heavy medium (heavy liquid or soliquiod).

The essence of gravity separation processing is summarized as a loose-layered-separation process. The loose action of the fluid must obey the requirement of stratification of the granules. The problem of gravity separation theory is simply to explore the relationship between looseness and stratification. The layered ore layers are discharged separately under mechanical action, that is, sorting is achieved.

Particle separation methods, looseness is a condition, stratification is the goal, and separation is the result.

2 The working principle of gravity separation

Most gravity separation processes involve two stages: loose-stratified and transport-separated. In the moving medium, the loose ore clusters form stratification of different density (or particle size) ore particles due to differences in the state of motion during settling. The layer of the good layer (ie the layer of material consisting of the ore particles) is separated by the transport of the moving medium. The basic law can be summarized as loose (settling) stratification (transport) separation. In fact, loose stratification and separation of operations are almost always occurring simultaneously. But looseness is a condition of stratification, and stratification is the basis of separation. The settlement is the most basic form of exercise. Looseness can be seen as a special form of sedimentation of ore particles in a rising medium flow.

2.1 The difference in density of different minerals in the ore is the basic condition for gravity separation

The density and particle size of the ore particles determine the weight of the particles and are the basic forces that push the particles to move in the medium. The different weights of the core particles are subject to different gravitational fluid dynamics and other mechanical forces in the medium, and their movement speed and motion. The trajectory is also different.

2.2 Mechanical action provides media to form motion and promote material stratification

The gravity separation process only is carried out in the moving medium. The ore particles are not easy to lose in the static medium, and the positions of the ore particles of different densities, sizes, and shapes cannot be transferred to each other, and even if the layering is reached, it is difficult to achieve separation. Only a moving medium can loosen the tight material layer. Mechanical action is the source of energy for media motion.

3 Gravity separation equipment

(1) Classification (2) Washing (3) Heavy media separation (4) jigging separation (5) shaker (6) chute (7) spiral classification (8) centrifugal concentrator (9) wind beneficiation (10) vertical gravity separator

Grading and washing are separated by particle size and are often used in the preparation of ore before the selection.

4 Common features of various gravity separation methods

(1) There must be a difference in density (or particle size) between the ore particles;

(2) The sorting process is carried out in a moving medium;

(3) Under the combined action of gravity, fluid dynamics, and other mechanical forces, the ore particles are loose and stratified by density (or particle size);

(4) Separate the layers of materials, achieve separation under the movement of moving media, and obtain different final products.

5 Application of gravity separator

Gravity separator is suitable for the treatment of ore or other materials with a large density difference between useful minerals and gangue. It is an effective method for treating ore, medium and fine (substantially bound to be larger than 25 mm, 25-2 mm, 2-0.1 mm) ore. In the treatment of fine slime (less than 0.1 mm), the efficiency is not high, the modern membrane casting equipment can effectively recover the particle size to 20-30 microns, and the centrifugal concentrator can reach 10 microns.

The gravity separation method widely used in dressing tungsten, tin, gold ore, iron ore, especially for the treatment of gold, tin ore, coal. gravity separation is very popular in the mineral separation plant.

6 Characteristics of gravity concentration methods in mineral processing

(1) The granularity of useful mineral inlays restricts the sorting effect;

(2) There is much sorting equipment and the process is relatively complicated;

(3) The ore size of the gravity concentrator is wide, up to several tens of millimeters;

(4) The structure of the gravity concentrate equipment is generally simple, does not consume expensive materials, and the operation is low;

(5) Less pollution in the environment.

7 Advantages of gravity separator machine

Gravity separation of ores is capable of various particle sizes at low cost, coarse (greater than 25 mm), medium (25 to 2 mm) and fine (2 to 0.075 mm) ore. Gravity separation metallurgy has a high processing capacity, low energy consumption, and cost.

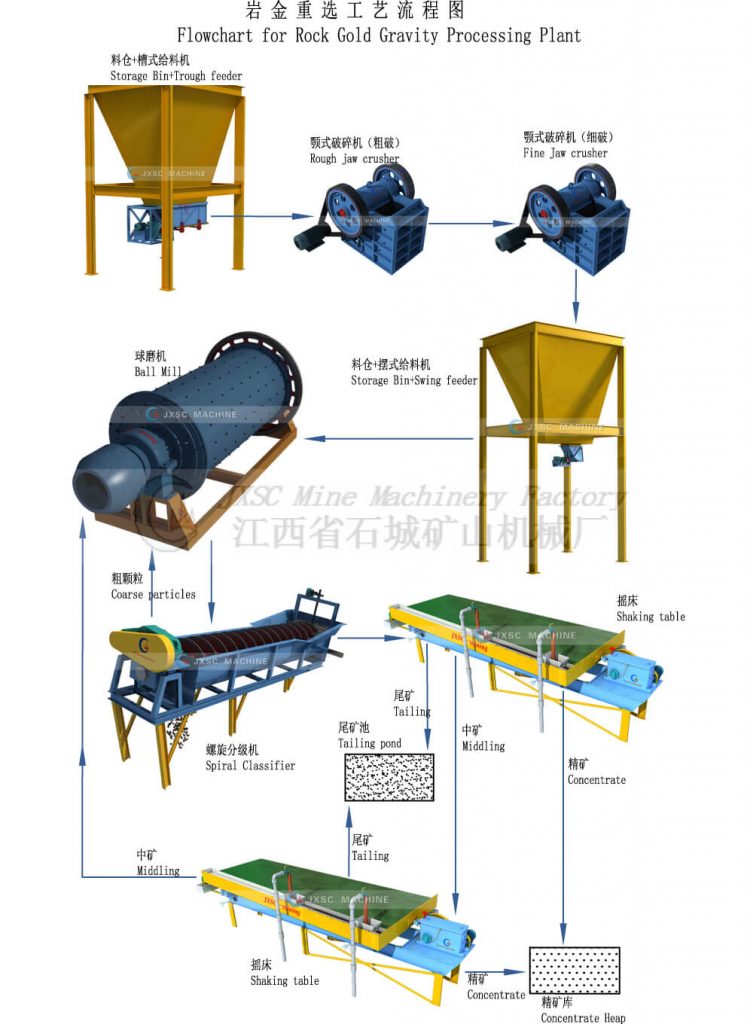

8 Gold gravity separation examples

Gravity separation is the most effective method for processing ore and coal such as gold, tungsten, and tin. It is also commonly used to recover rare rocks, ilmenite, rutile, zircon, monazite, coltan, and coltan, and non-ferrous metal minerals, also used for sorting coarse-grained inlays and a few fine-grained hematite ores and manganese ore and non-metallic minerals and solid waste such as asbestos and diamond.

The concentrator uses the heap leaching-gravity separation-cyanide carbon leaching process to recover the gold in the ore and obtains a satisfactory technical and economic index. The recovery rate of gold exceeds 80%. The economic and social benefits of the concentrator are very significant. The production process of the gravity separation examples is shown below.

JXSC gravity separator for sale! We provide types of gravity separators, multi-gravity separators, build a close relation with Africa mining companies, contact us to get the gravity separation diagram.