Nickel is a metallic mineral that is ductile, ferromagnetic and resistant to corrosion. It is the main constituent element of stainless steel, nickel-based alloy and alloy structural steel. It can be widely used in special steel, electroplating, battery, aerospace materials and military industry. According to the properties of nickel ore, it can be divided into copper-nickel sulfide ore and nickel oxide ore, and the beneficiation methods are different. Among them, more than 60% of the world's nickel metal resources come from copper-nickel sulfide deposits. In addition to metallic copper and nickel minerals, this type of copper-nickel ore is often associated with rare and precious metals such as gold, silver, platinum, and palladium, all of which have good recovery value.

Generally, copper-nickel sulfide ore usually adopts flotation process. Due to the difference in ore type, mineral content and associated precious metal content, the flotation separation process used in copper-nickel ore is also different. It mainly includes priority or semi-priority flotation separation process, mixed flotation separation process, fast flotation process, etc.

Copper-Nickel Sulfide Ore Beneficiation

In copper-nickel sulfide ores, copper exists in the form of chalcopyrite. Nickel exists in the form of free nickel sulfide, such as pentlandite, pentlandite, and purple sulfur nickelite. A considerable part of nickel exists in pyrrhotite in the form of isomorphism. There are many beneficiation methods for this type of nickel ore, such as flotation, magnetic separation, gravity separation, etc., but flotation is the main separation method.

1. priority flotation process

The process is mainly for ores with high copper content and low nickel content and simple properties. The priority flotation process of copper-nickel sulfide ore usually adopts the process of "floating copper and suppressing nickel". The separation of copper and nickel is achieved by adding inhibitors of nickel sulfide minerals and high-efficiency collectors of copper. It is suitable for processing copper-nickel minerals with higher copper content than nickel, and the copper concentrate is preferentially flotation.

- Advantages: Copper concentrate with low nickel content and qualified nickel concentrate can be obtained directly, and the cost is low.

- Disadvantages: The suppressed pentlandite and purple sulfur nickel ore during copper flotation are difficult to activate in subsequent flotation, resulting in low nickel recovery rate and waste of nickel resources.

2. Mixed flotation of copper-nickel sulfide ore

Mixed flotation of copper-nickel sulfide ores is mostly suitable for sorting copper-nickel ores with lower copper than nickel content. The process method is to extract copper and nickel minerals by mixing and flotation from the ore, and then separately select copper concentrate (containing low nickel) ore and nickel (containing low copper) concentrate from the mixed concentrate. The obtained nickel concentrate can be directly smelted.

(1). Copper-nickel mixed flotation re-separation process

Copper-nickel mixed flotation-the flotation process of mixed concentrate to suppress nickel and float copper is the most commonly used copper-nickel beneficiation process in copper-nickel sulfide ore beneficiation plants. The process is to first obtain copper-nickel mixed concentrate through copper-nickel mixed flotation. After the mixed concentrate is grinded to remove chemicals, the method of suppressing nickel and floating copper is used to separate copper concentrate and nickel concentrate.

(2). High nickel matte regrinding flotation separation process

The high-nickel matte regrinding flotation separation process refers to first adopting copper-nickel mixed flotation to obtain copper-nickel mixed concentrate, then mixing the concentrate to form low-nickel matte through electric furnace smelting. Then it is transformed into artificial high-nickel matte ore through converter blowing, and finally, the high-nickel matte ore is re-grinded and flotation-separated.

This process is mainly aimed at the ore whose copper-nickel associated relationship is complex and the particle size is extremely fine. The direct flotation copper-nickel separation method cannot complete the copper-nickel separation. High-nickel matte is mainly composed of Ni3S2, Cu2S, copper-nickel-iron alloy and a small number of platinum group elements. The iron content, sulfur content and copper-nickel ratio of high-nickel matte are important factors affecting the subsequent flotation separation process.

- Advantages: Compared with the layered smelting method, electrolysis method and leaching method, the flotation separation process of high-nickel matte has the advantages of short process and low energy consumption.

- Disadvantages: The flotation separation of high nickel matte usually suppresses nickel and floats copper under high alkali conditions. When the pH value of the slurry is too high, it will also have a certain inhibitory effect on Cu2S, and it is during the preparation of high nickel matte. Ni3S2 and Cu2S wrap each other, and xanthate is mostly used as collector. The selectivity to the two minerals is poor, and the inner containment of copper and nickel in the obtained concentrate is still not ideal.

3. Electrochemical control flotation process of copper-nickel sulfide ore

(1) Electrochemical control flotation is to change the electrochemical characteristics of flotation pulp by chemical agent control, adjust the buoyancy of minerals, and realize the flotation separation of minerals. In the flotation of copper-nickel sulfide ore, the potential regulation methods are as follows:

i. Controlling the oxidation process on the surface of copper-nickel sulfide minerals during grinding and flotation by oxidizing agents;

ii. By adjusting the pH value of the pulp, controlling the electrochemical characteristics of the copper-nickel sulfide mineral surface, and providing a reasonable flotation pulp environment;

iii Add chemicals to prevent excessive oxidation of copper-nickel sulfide minerals during flotation.

(2) Potential-regulated flotation can be divided into two types from the means of realization: chemical agent regulation and external electrode regulation. These two control methods are relatively mature, but each has its own advantages and disadvantages.

i. Chemical agent control method

This method does not require major modification of the original flotation equipment, and the control effect is better. However, a large amount of oxygen will enter the slurry system during aerated flotation, making it difficult to maintain the slurry potential within an appropriate range. Increased the amount of redox agent, which is unfavorable to the subsequent flotation.

ii. External electrode control method

The method has the advantages of simple and fast operation, and will not increase the unavoidable ions in the pulp. However, the original flotation machine must be modified and electrodes must be installed, resulting in higher installation and maintenance costs.

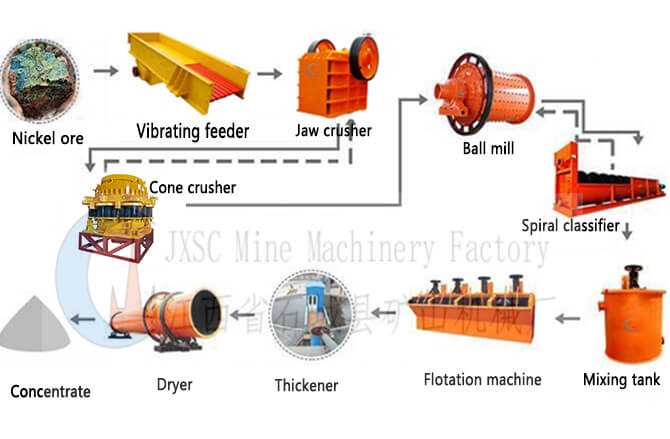

Copper Nickel Sulfide Ore Processing Plant

1. Crushing and screening: the mined copper sulfide ore is sent to the jaw crusher by the feeder for coarse crushing. The conveyor sends the coarsely crushed copper-nickel sulfide ore to the cone crusher for secondary crushing. The screening equipment screens the copper sulfide ore after the secondary crushing process, and the qualified ore particles can be directly sent to the next milling link. The unqualified ore particles must be returned to the cone crusher for crushing again.

2. Grinding and screening: Qualified copper-nickel sulfide ore particles are sent to a ball mill for grinding, and the ore particles are ground to form ore powder. It is sent to the spiral classifier for sorting treatment, and those whose particle size meets the requirements can go to the next step of flotation purification. Those that do not meet the requirements need to return to the ball mill for secondary grinding.

3. Flotation separation: the copper-nickel sulfide ore with qualified grinding powder is sent to the flotation machine for flotation. For the specific flotation method, it is necessary to find a professional beneficiation manufacturer, conduct a beneficiation test and analysis of its mineral properties, and after professional analysis, customize a purification process that meets the actual situation.

4. Dehydration and drying: the water content of the material after flotation is relatively large. To speed up the drying speed of the product, thickener is usually selected for dehydration and separation. Then dry it with a dryer to get the finished product.

The above is the application of flotation process and beneficiation equipment of copper-nickel sulfide ore. In the actual beneficiation plant, the beneficiation test should be carried out first, and the nickel ore beneficiation method should be scientifically and rationally designed according to the test results to obtain the ideal beneficiation plant benefit. JXSC Mining Machinery can customize various types of ore processes and mining equipment for you, with 35+ mineral processing experience, safe and reliable, contact our professional engineers for consultation.