Metal deposits represent a vital component of mineral resources, formed through complex geological processes over extensive periods of geological evolution. These deposits exhibit distinctive characteristics that directly influence exploration challenges and economic viability. A thorough understanding of these features is crucial—not only for geological research and mineral prospecting, but also for providing a scientific foundation for mine design and operations. This article examines key features of metal deposits, including their complex geological occurrence conditions, variable orebody morphology, fluctuating ore grades, structural complexities, rock mass competency, and water content—analyzing their impacts on mining operations and economic returns while proposing corresponding technological solutions.

Key Features of Metal Ore Deposits

1. Complex Occurrence Conditions

One of their most notable characteristics is the extremely complex occurrence conditions of metal ore deposits. The thickness, dip, and shape of the ore body exhibit instability. Within the same ore body, these parameters can vary significantly, both along strike and inclination. Take China's renowned Dexing Copper Mine as an example, the thickness of the ore body along strike varies from a few meters to several dozen meters. In some areas, the thickness suddenly thins, even experiencing a pinch-out phenomenon. Furthermore, along inclination, the dip angle can gradually change from gentle to steep. This morphological variation in the ore body poses significant challenges to mining.

Ore bodies often exhibit pinch-outs, branching, and recombination, further increasing the difficulty of mining. In some metal deposits, the ore body can suddenly interrupt during its extension, known as pinching out, and then reappear at a certain distance. This phenomenon disrupts the continuity of the ore body, greatly complicating mining planning. Branching and recombination occur when an ore body splits into multiple smaller ore bodies during its extension and then re-merges into a single ore body. This makes the ore body's morphology more complex and makes it difficult to accurately grasp its distribution patterns.

These complex and variable geological conditions place extremely high demands on mining planning and technology. Mining planning requires a precise understanding of the ore body's morphology and distribution to rationally arrange mining tunnels and stopes. However, due to the instability of the ore body, traditional exploration methods often struggle to accurately capture this information. This necessitates the use of advanced exploration technologies, such as 3D seismic surveys and high-precision drilling, to improve exploration accuracy. Mining technology requires selecting the appropriate mining method based on the ore body's specific conditions. For ore bodies with significant thickness variations, staged or layered mining may be necessary. For ore bodies with significant inclination variations, different mining techniques should be considered. For example, gently inclined ore bodies may be mined using the room-and-pillar method, while steeply inclined ore bodies are more suitable for shaft development and sublevel caving.

2. Large Ore Grade Variations

The ore grade of metal deposits often varies significantly along the strike and dip of the ore body. This variation sometimes follows certain patterns, such as the ore grade becoming poorer or richer with increasing depth. For example, in some lead-zinc deposits, the lead and zinc grades are higher in shallow ore bodies and gradually decrease with increasing mining depth. In contrast, in other copper deposits, the copper grade in deeper ore bodies is actually higher than that in shallower areas.

Ore grade fluctuations have a significant impact on mineral processing technology and economic benefits. In terms of mineral processing technology, grade fluctuations require greater adaptability. When the ore grade is high, the mineral processing process is relatively simple, and conventional processes such as crushing, grinding, and flotation can be used to obtain a high-grade concentrate. However, when the ore grade is low and fluctuates significantly, the mineral processing process needs to be optimized and adjusted. It may be necessary to increase the grinding fineness to improve the monomer dissociation of useful minerals or adjust the type and dosage of flotation reagents to enhance the capture of useful minerals in low-grade ore.

From an economic perspective, changes in ore grade are directly related to a mine's profitability. High-grade ore generates higher sales revenue, but also comes with relatively higher mining costs. Low-grade ore, while cheaper to mine, also generates lower sales revenue. Excessive grade fluctuations can make production planning difficult, reduce equipment utilization, and increase production costs. A sudden drop in ore grade can reduce concentrate production and quality at the concentrator, impacting sales prices and the company's economic returns. Therefore, accurately understanding the changing patterns of ore grade is crucial for rationally scheduling production, optimizing beneficiation processes, and improving mine economics.

3. Complex Geological Structures

Metal ore deposits often contain a variety of complex geological structures, such as faults, folds, veins penetrating the ore body, and fault fracture zones. These geological structures have a multifaceted impact on ore mining.

Faults are a common geological structure that can cause dislocation and displacement of the ore body, disrupting its continuity. When faults are encountered during mining, ore loss and dilution may occur. Ore bodies on either side of the fault may shift relative to each other, making it difficult to determine the mining boundary. Some ore may be left on one side of the fault, resulting in ore loss. Furthermore, rock from the fault fracture zone may mix with the ore, leading to ore dilution.

Fold structures can alter the ore body's shape and occurrence, increasing mining difficulties. Folded areas can cause the ore body to bend and twist, requiring mining plans to adapt to this complex ore body shape. When designing mining tunnels, the impact of folds must be considered, and the tunnel's direction and slope must be rationally planned to ensure smooth mining operations.

Veins penetrating an ore body can alter its structure and properties, affecting the quality of the ore. Veins are often composed of different rocks, with varying hardness and chemical composition from the ore body. When these veins penetrate the ore body, they can cause the ore's composition to become uneven, impacting subsequent beneficiation and smelting processes. Some veins may contain harmful elements, such as sulfur and arsenic, which can reduce ore quality and increase the difficulty of beneficiation and smelting.

Fault fracture zones not only affect the integrity of the ore body but also pose a threat to mining safety. The rock in these fracture zones is highly fragmented and unstable, making them prone to collapse during mining, endangering the lives of workers. Therefore, a detailed geological survey of fault fracture zones is necessary before mining, and effective support measures, such as bolting and cable anchoring, must be implemented to ensure safe mining.

4. High Solidity of Ore and Surrounding Rock

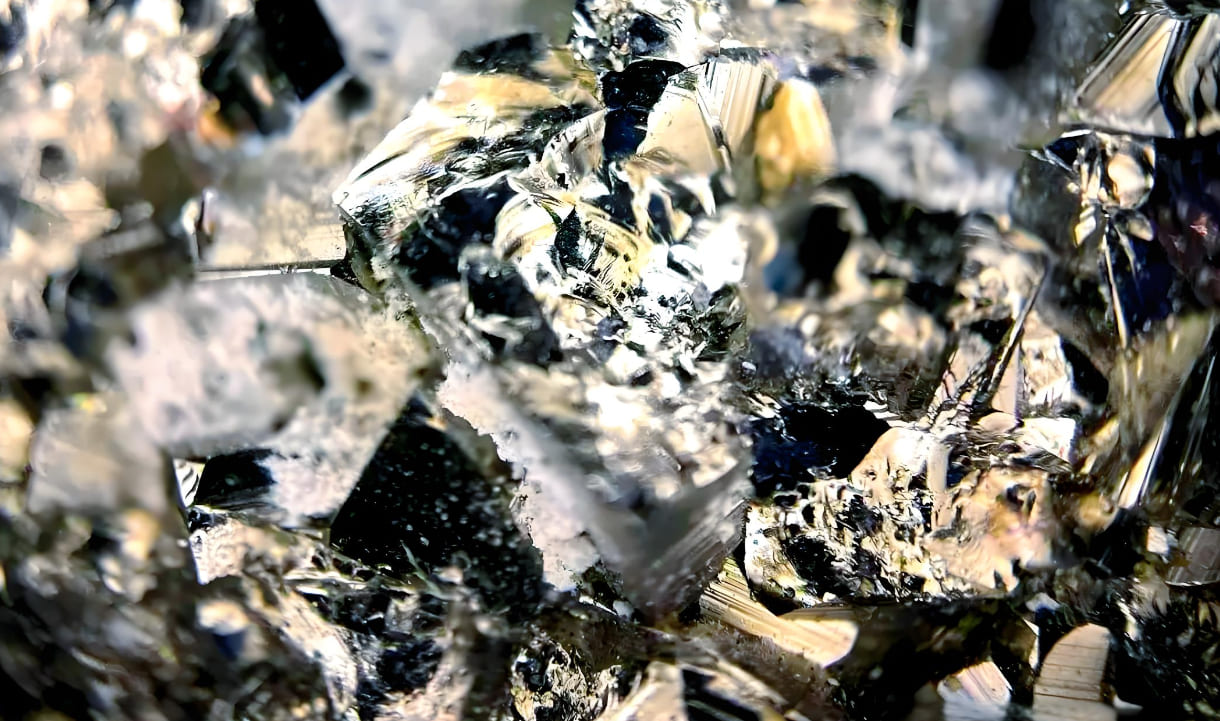

The ore and surrounding rock of metal deposits are typically very solid, which necessitates the use of rock drilling and blasting to break the ore and surrounding rock during mining.

This high solidity creates certain challenges for implementing comprehensive mechanized mining. Comprehensive mechanized mining requires that the ore and surrounding rock have good workability to enable efficient operation of mechanical equipment. However, for highly solid ore and surrounding rock, ordinary mechanical equipment is difficult to use directly mine. Rock drilling and blasting are required to break the ore into smaller pieces before subsequent mining operations can proceed. This not only increases mining processes and costs, but also reduces mining efficiency.

To cope with highly solid ore and surrounding rock, advanced mining technologies and equipment are required. In terms of rock drilling technology, efficient rock drilling equipment, such as hydraulic rock drills, can be used. These offer advantages such as high drilling speed, high drilling accuracy, and low energy consumption, improving drilling efficiency. In terms of blasting technology, advanced blasting techniques such as micro-difference blasting and pre-splitting blasting can be employed. These techniques can effectively control blasting vibration and flyrock, improving blasting effectiveness and minimizing damage to the surrounding rock mass.

In terms of equipment selection, appropriate mining equipment should be selected based on the strength of the ore and the surrounding rock. For harder ores, high-powered excavators and loaders can be used to ensure efficient excavation and loading. Furthermore, equipment maintenance and management must be strengthened to ensure proper operation and extend its service life.

5. Water Content

Another key characteristic of metal deposits is the presence of significant water, which significantly impacts mining operations.

Water content in ore deposits primarily increases the investment in drainage equipment and facilities. To ensure the normal operation of mining operations, a large amount of drainage equipment, such as pumps and drainage pipes, is required to remove accumulated water from the mine. The purchase, installation, and maintenance of this drainage equipment are costly, increasing mining costs.

Excessive water content can significantly hinder mining operations. Water-containing crushed ore easily agglomerates and clogs the hopper, hindering the proper discharge of ore. During the discharge process, agglomerated ore may become stuck at the hopper mouth, hindering discharge and requiring manual unblocking. This not only reduces discharge efficiency but also increases labor intensity and safety risks for workers.

Water content in ore deposits also reduces the stability of the surrounding rock. The presence of water alters the mechanical properties of the rock, reducing its strength and stability. The stability of the surrounding rock is crucial during the mining process. If the surrounding rock becomes unstable due to water content, it can lead to accidents such as roof collapse and spalling, endangering the lives of workers.

To address water problems in ore deposits, effective drainage and waterproofing are necessary. For drainage, use a combination of centralized and segmented methods. Arrange a rational system based on the mine’s topography and hydrogeology. This ensures the timely and effective removal of water. For waterproofing, use methods like curtain grouting and waterproof pillars. These blocks block groundwater inflow and reduce water ingress. It is also necessary to strengthen the monitoring and early warning of water inflow. This helps track conditions and take appropriate action.

Conclusion

In summary, metal deposits demonstrate highly complex occurrence conditions with unstable orebody geometries, fluctuating grades, and diverse structural features—all posing significant challenges for mineral extraction. However, advancements in mining technologies—such as 3D exploration, intelligent mining systems, and advanced dewatering techniques—provide increasingly effective solutions. Sustainable development of metal resources depends on rigorous geological understanding, optimized mining methods, and efficient processing workflows. As resource demands grow and environmental regulations intensify, continued research into deposit characteristics and adaptive mining technologies will remain critical for the industry's sustainable future.