When setting up a compact yet efficient tin processing plant, balancing production capacity, recovery rate, and operational simplicity is key—especially for small-scale miners. This walkthrough details a tailored 5-ton-per-hour (TPH) rock tin processing plant for a Ugandan client, addressing equipment selection, process flow, and customer-specific FAQs. Whether you're exploring tin beneficiation or upgrading an existing setup, these insights highlight practical considerations—from jig machine optimization to dewatering solutions—that ensure cost-effective, high-recovery operations.

5TPH Rock Tin Processing Plant

Customer’s Rock Tin Project Information

Rock Stone Mine Location: Uganda

Raw Ore Condition: Hard tin, need crush, fine tin concentrate.

Customer’s Main Requirements: 5tph as a small start, higher recovery rate. High-quality machine and fast goods delivery. Need a dewatering machine to recycle some water and tailing sand with less moisture.

5TPH Rock Tin Processing Plant Flowchart

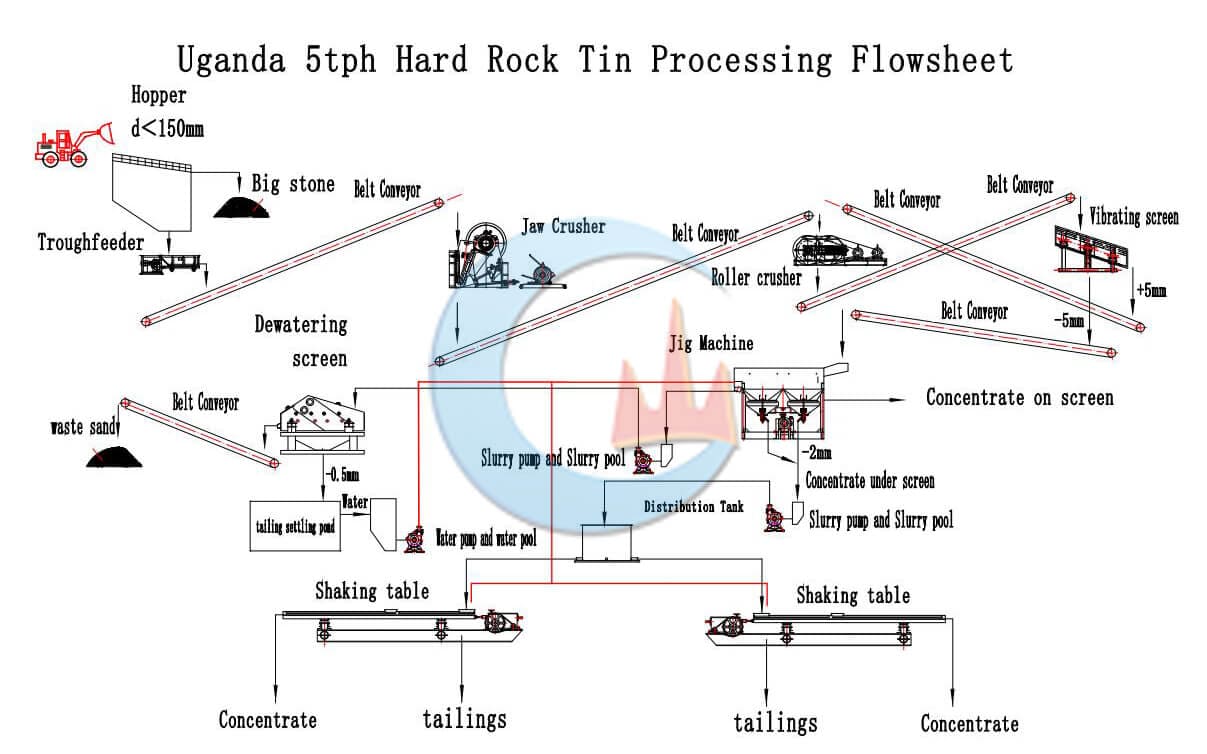

The process is as follows:

1. The raw ore is fed into a hopper by an excavator; the hopper has a grizzly bar, which separates the big stones bigger than 150mm as required.

2. Under the hopper, use a trough feeder to feed the material evenly to the belt conveyor.

3. The belt conveyor transports the stone to the jaw crusher. The input stone sizeis around 120mm(actually, the client's raw stone is less than 100mm) to be crushed into smaller pieces around 30mm.

4. The output from the jaw crusher goes to the second stage roller crusher by conveyor.

5. The roller crusher is used to crush the stone size 30mm into fine gravel around 5mm.

6. The vibrating screen for screening here. The bigger than 5mm goes back to crush again, and the smaller than 5mm goes to a jig machine.

7. The smaller than 5mm will be fed into the jig machine for tin separation by a conveyor. The jig machine with 2mm screen mesh aperture. The 2-5mm over screen as concentrate, the <2mm under jig screen will be fed into the shaking table by the slurry pump.

8. The shaking table for fine tin separation. Which can improve the upgrade. As there are two sets of shaking tables, use a distribution tank before them for better feeding.

9. A dewatering screen required by the client needs to recycle the tailings water from the jig and shaking table.

10. Near the dewatering screen, there are at least two tailings settling ponds required. The under-screen <0.5mm particles will go to tailings settling ponds for sedimentation for reuse. The overscreen>0.5mm as waste sand and transferred away by the belt.

FAQ During Communication

Question: Regarding the Jig Machine, Need Duplex Diaphragm Jigs. What about the Ragging Material (as Jigs will best perform with Ragging material)?

Answer: Iron ore is adopted as a heavy medium. In view of the requirement that the jig screen is to be made with a 5 mm aperture, it is recommended that the particle size of iron ore be controlled at 6–20 mm.

Question: Trough Feeder / 600*500mm. Is there any Support to fix / or how to fix the Coarse Ore Feed Bin?

Answer: Dear, normally it hangs under the hopper.

Question: Trough Feeder / 600*500 mm. Is any Inside trough liner present or not (to avoid wear & tear of Hard rock)?Answer: There is no additional liner. If you still require, we can customize for you, while addtional cost will be charged. The picture of the trough feeder is for your reference.

Question: Regarding the Shaking Table (New-type) / 6S-4500, the size of the table is Fine riffles (not the coarse, we don’t want coarse riffles on the tables)

Answer: Okay, no problem, we have a slime deck.

Questions: Can you make a 2kw motor (instead of 1.1kw)?

Answer: We strongly suggest keep 1.1kw, it’s totally enough. If you still require 2kw motor. Then we can customize it also.

Question: Is any Product collector Launders also providing along with the table?

Answer: See our new shaking table picture, with the PP material collecting and feeding chute.

Question: After sales, if needed, then to be reply if any quarries if we have a later stage( Some vendors will not even reply once sales are done)?

Answer: Once made deal with us, we will provide life-long service for you (that means for all the mining equipment or mining solutions, etc., not only for the tin plant, also free to other minerals ). We are factory since 1985. The good quality and good service help our business go further, and we will cooperate more and more.

Conclusion

This 5TPH tin plant exemplifies how tailored solutions—from crusher selection to after-sales commitments—can empower small-scale miners. By prioritizing high recovery rates, modular scalability, and water-efficient designs, Ugandan operators can sustainably tap into hard rock tin deposits.

Interested in optimizing your mineral processing? Share your project specs—we’ll help you balance cost, recovery, and operational simplicity.