Study on Knelson Concentrator Gravity Separation of a Polymetallic Ore Bearing Gold

The major methods of recovering gold are gravity separation, gold flotation, cyanide. In fact, traditional gravity separators, such as jig machine, spiral chute, gold shaker table, have the shortages of low beneficiation ratio and low productivity.

In addition, the flotation process is difficult to work on the coarse grain gold minerals which with heavy density. Considering environmental protection, the application of gold cyanide method is also greatly limited.

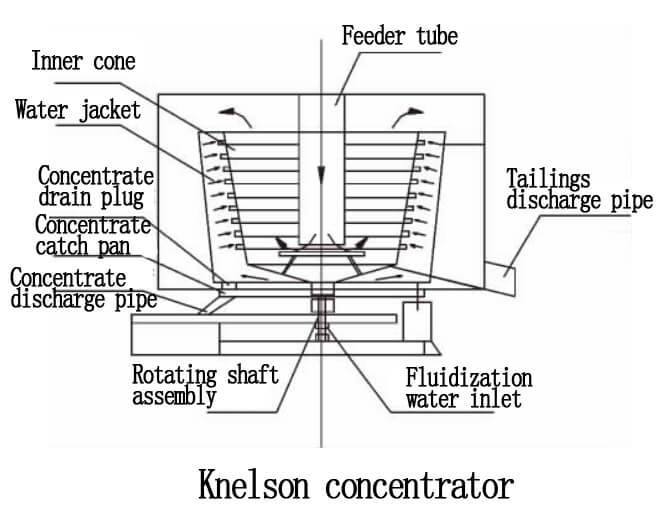

Compared with the commonly used gold recovery methods, Knelson (centrifugal) concentrator is an efficient centrifugal mineral processing equipment, has great advantages of capable to recovering coarse, medium, fine grain gold, high beneficiation ratio and no pollution.

Mine is a typical porphyry type gold-copper deposit, with low-grade gold-bearing refractory ore. as shown in the processing result, the efficiency of recovering associated gold is very poor. In this experiment, we carry out the gravity separation experimental of the knelson concentrator, trying to provide the technical basis for improving the recovery efficiency of associated gold ore.

1 Raw gold ore property

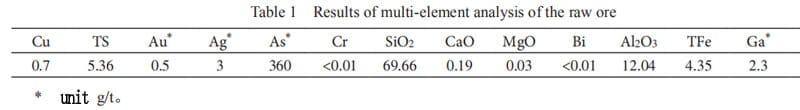

1.1 Chemical composition

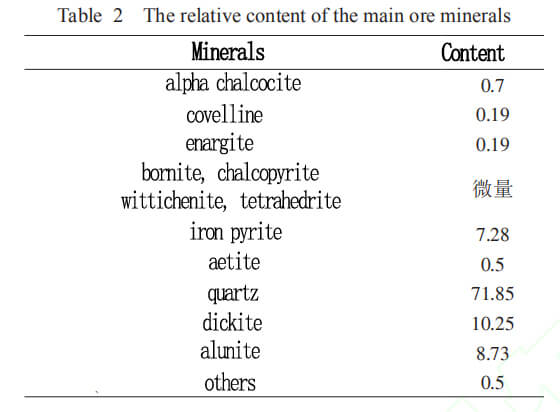

Copper and iron are the two main elements in the raw ore, and exist in the forms of alpha chalcocite, covelline, enargite, iron pyrite. The gangue minerals are mainly quartz, dickite, alunite, and a small amount of iron oxide, etc. Gold symbiosis with other minerals closely, that is the raw ore is multi-metal gold-bearing refractory ore.

1.2 Mineralogical analysis

Based on the analysis of the occurrence state and distribution of gold in the overflow ore, it is found that a large part of the gold is dissociated from the raw ore, the visible gold in the overflow ore accounts for 36%. It can be seen from the distribution of gold in the ore that improving the recovery of visible gold is the key to increase the recovery rate.

Taking enrichment and gold mineral scanning processes for the part of overflow ore, obtain 80 gold minerals. According to the count of grain ore size, the visible gold is mainly fine-grained grade, in which, 10 ~ 80 μm account for 80%, few are less than 10μm. In view of the previous research, gold particles over 37 m can be recovered by gravity separation, while 10 ~ 37 m is more suitable for flotation processing. click to find more info about Fine gold recovery equipment.

2 Experimental procedure

The ore sample is a low-grade gold bearing refractory copper ore, in which, gold is closely associated with copper-sulfur minerals, the gold( mainly in nature gold) are distributed in the gaps. After the ore was dissociated, a large part of gold became granular gold, and it was difficult to achieve effective recovery by flotation, so the Knelson is used to pre-recover the granular gold.

2.1 Sample Screening

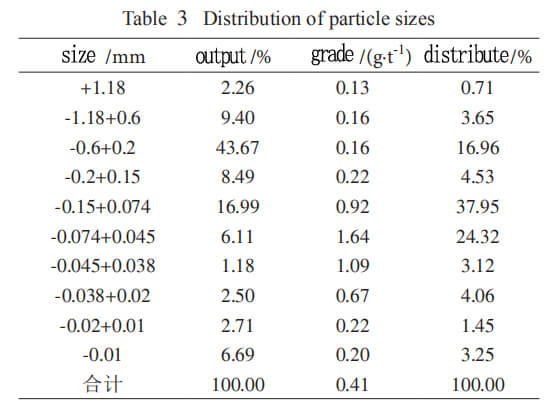

The Knelson centrifugal concentrator is often arranged at the outlet of the ball mill, we analysis the ball mill discharge firstly, to know the metal distribution of different particle sizes.

As can be seen in the above table, the major particle size is 0.045mm-0.6mm, with 75.26% of productivity, and the distribution rate of gold is up to 83.76%. The recovery result of this grain size will directly affect the recovery effect of the final gold metal.

2.2 Knelson concentrator gravity separation

- Machine: KC-MD3 Knelson concentrator and shaker table for gold recovery

- Experimental variable: gravity, fluidized water, fluidized water, feeding rate.

- Sample ore size: -1mm

- Content of gold: 0.55 g/t

- Experiment condition: pulp density 30%, feeding rate 1 kg/min, fluidized water 3.0-3.3 L/min, enrichment time 25min, gravity range 40-120G.

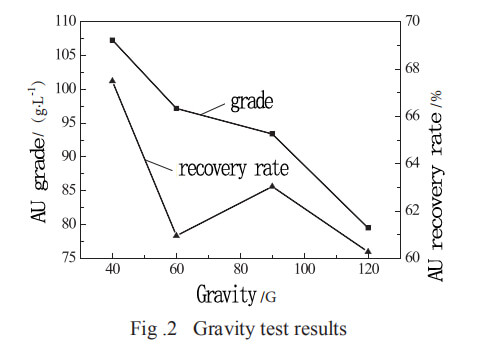

【2.2.1 Gravity Test】

From the experimental results, with the increase of gravity value, the concentrate gold grade and recovery rate of Knelson gravity decreased. The lower gravity value is beneficial to Knelson to concentrate gold. When the gravity value is 40G, the grade of gold concentrate is 107.28 g/t, and the recovery rate is 67.49%.

【2.2.2 Fluidized water】

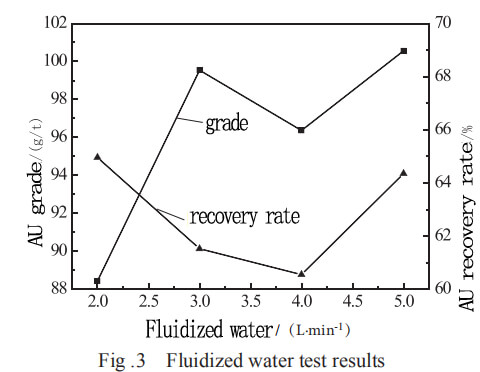

Experiment condition: pulp density 30%, feeding rate 1 kg/min, gravity value 40G, enrichment time 25min, fluidized water have 2L/min, 3L/min, 4L/min, 5L/min.

The result shows that with the increase of fluidization water flow, the grade of gold concentrate tends to rise, the recovery rate is changed slightly. When the water flow is 5.0 L/min, the concentrate is 100.56 g / t, and the recovery rate is 64.35%.

【2.2.3 Enrichment time】

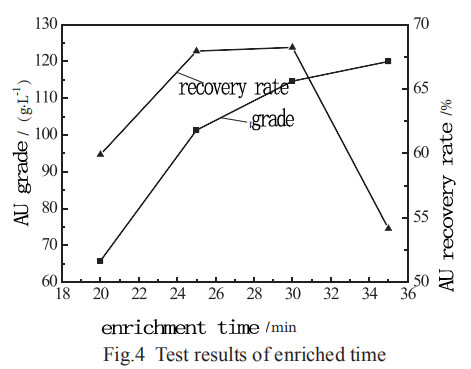

Experimental conditions: pulp density 30%, ore feeding speed 1 kg/min, gravity value is 40G, fluidization water 5.0 L/ min, enrichment time have 20 minutes, 25 minutes,30 minutes and 35 minutes.

With the increase of enrichment time, the grade of concentrate increases gradually, and the recovery rate increases at first and then decreases. When the enrichment time is 30 min, the maximum value is 68.23%, and the concentration level is 114.63%.

【2.2.4 Feeding speed】

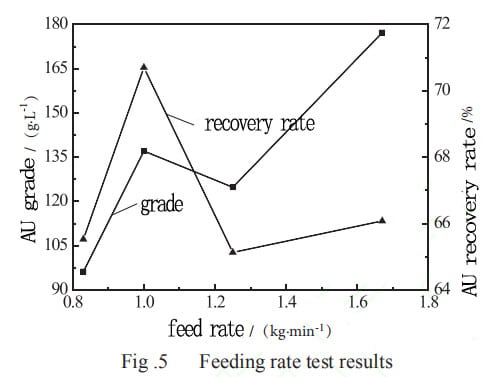

Experimental conditions: pulp density 30%, gravity value is 40G, fluidization water 5.0 L/ min, enrichment time 30min.

As the feeding rate is increased, the grade of concentrate has a tendency to rise, and the beneficiation effect is gradually enhanced, the recovery rate is increasing at first and then decreased. when the feeding rate at 1 kg/min, the recovery rate up to the max value of 70.70%, the grade is 137.12g/t. Considering the stability of Knelson concentrator, the most suited feeding speed is 1 kg/min.

【2.2.5 Enlarged experimental of combined variables】

On the basis of the preliminary experiments, researcher adopt KC-MD 7.5 Knelson concentrator to carry on combined variables experimental of discharged ore of ball mill.

Experimental condition: process ore 600 kg, particle size -2mm, pulp density 30%, feeding rate 300-400kg/h, gravity value 40G, fluidization water pressure 0.2-0.3 Mpa.

Knelson gravity concentrator has a good effect on gold enrichment, and obtain a high grade of concentrate. The gold content of the concentrate is 251.30 g/t, the recovery rate is 53.70%, and the Knelson has not affected the recovery of copper.

2.3 Advanced analysis

【2.3.1 Gold recovery efficiency】

From the analysis of Knelson concentrate and tailings, Knelson concentrate has the best recovery effect on -0.6+0.038mm, followed by +0.6mm, and finally -0.038mm.

【2.3.2 Granular gold recovery】

The grain size range of gold minerals is 0 ~ 800 μm, and the particle size distribution of gold particles is mainly concentrated in the range of 20 ~ 100 μ m( 69%). The gold particles less than 30 μm account for only about 8%, the recovery rate of that is low.

The gold particles larger than 150 μm in the concentrate account for 13%, of which only about 1% are more than 360 μm. This part of the particulate gold is difficult to be recovered by flotation.

Recovering the great mass of gold by Knelson gravity separation can effectively reduce the sedimentary gold in the flotation machine, and avoid the repeated grinding.

Conclusion

Using Nielsen concentrator which obtains synthetic recovery of -0.6+0.038 mm gold. Nielsen concentrator, the pre-recovery of most of the particles of gold, can reduce the loss of gold in flotation operations, achieving the goal of the income received early.

About JXSC Mining Machinery

JXSC starts mining equipment manufacturing in 1985 and has rich experience in mining equipment among various minerals and professional solutions for mineral processing plant, is a reliable provider of gold separator machine and gold recovery equipment. If you would like to receive more mining engineering news, please consider follow us to receive updates on the gold extraction process.