Cobalt Ore Mining Process

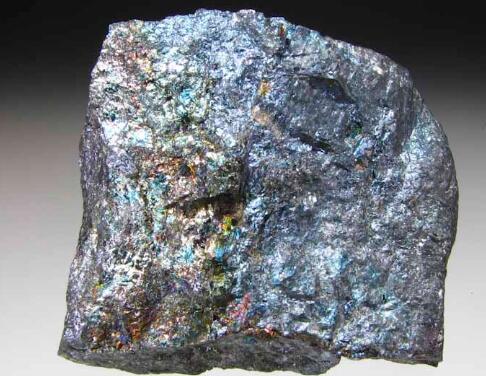

What is Cobalt Ore

Cobalt (Co) is a bluish-gray, shiny, brittle metallic element. It has magnetic properties similar to iron. There are no significant minerals of cobalt. It is rare and obtained mostly through refining of nickel ore. It is used in super alloys for jet engines, chemicals magnets, and cemented carbides for cutting tools. Principal cobalt-producing countries include Democratic Republic of the Congo, Zambia, Canada, Cuba, Australia and Russia. The United States consumes about one-third of total world production. Cobalt resources in the United States are low grade and production from these deposits is usually not economically feasible.

Cobalt Ore Mining

Cobalt is recovered through nickel mining operations as a by-product of refining. It is estimated that there are about 1 million tons of available by-product cobalt in the United States. Minnesota has the largest nickel deposits followed by Alaska, California, Idaho, Missouri, Montana, and Oregon. The identified cobalt resources in the world total about 15 million tons.

The ocean floor has manganese nodules that form when hot water from deep in the Earth comes into contact with the cold ocean water. It is estimated that there are millions of tons of cobalt in these nodules, however, it is not currently cost-effective to retrieve these nodules.

All of the primary cobalt used in the U.S. is imported in the form of cobalt metal, cobalt salts, and cobalt oxide. The imports come primarily from Norway, Finland, Canada, and Russia.

Cobalt Ore Uses

Cobalt has been used by civilizations for centuries to create beautiful deep blue glass, ceramics, pottery and tiles. In a similar way, it is being used to make paint pigments.

In addition to these traditional uses, cobalt is used in a number of industrial applications. When cobalt is alloyed with other metals, very strong magnets are created. Superalloys containing cobalt are used in the production of jet engines and gas turbine engines for energy generation. These superalloys account for nearly half of the cobalt used each year. Some cobalt is used to make cutting and wear-resistant materials.

A synthetic isotope of cobalt, cobalt-60, produces gamma rays. This is used for sterilization of medical supplies and foods, for industrial testing and to fight cancer.

Cases Study - Cobalt Ore Mining

100TPH Rock Copper & Cobalt Ore Process Plant In Congo

Raw Material: copper oxide ore

Capacity: 100TPH

Country: Congo

Feeding size: 0-300mm

Raw mineral description: Mineral composition: copper 1.8-2% and don’t kown the cobalt content.

Customers requirements: the lead and barite grade should reach 25-30%. The concentrate can be a copper-cobalt mixed concentrate. And raw ore only needs to be crushed below 2mm.

---Read more---