Metal deposits, as precious treasures bestowed upon humanity by nature, have consistently held a pivotal position throughout the evolution of human civilization. From ancient times, when humans serendipitously discovered natural metals, to the present era of large-scale mining and the widespread application of various metals in modern industry, metal deposits have remained a key driving force behind societal development and progress.

What Exactly Are Metal Deposits?

Not all rocks containing metals qualify as deposits - the difference lies in concentration and economics.

A metal deposit must contain sufficient metal concentration (grade) and quantity (tonnage) to justify extraction. Geological processes like magma crystallization, hydrothermal activity, or sedimentation create these concentrated metal accumulations over millions of years.

Key Components of Metal Deposits

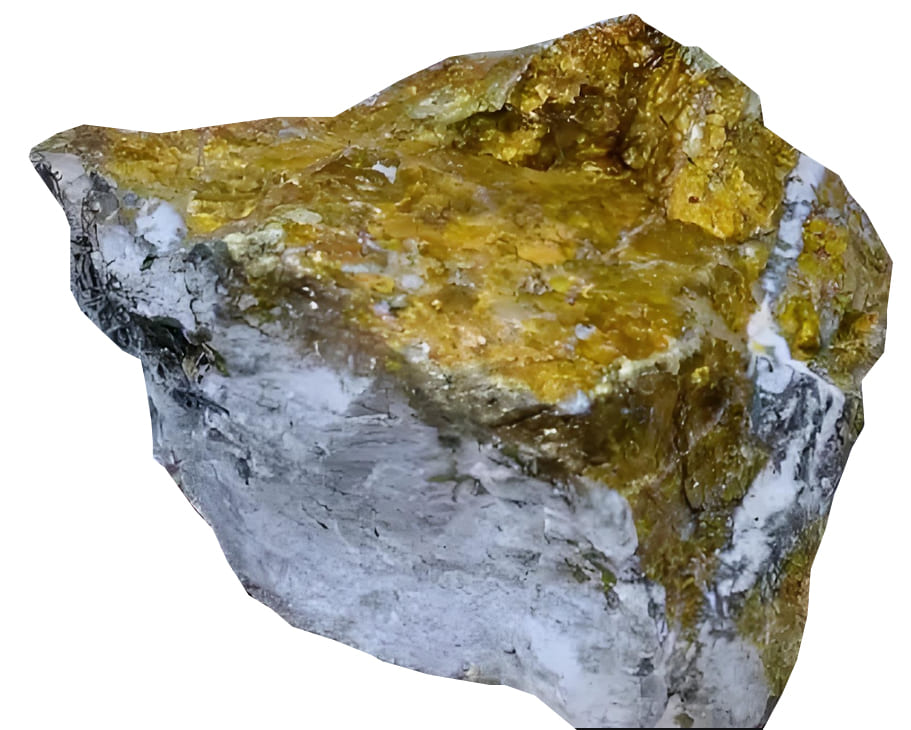

- Host rock: The surrounding geological material

- Ore minerals: Metal-bearing compounds (e.g., chalcopyrite for copper)

- Gangue minerals: Non-valuable accompanying materials

Formation Processes

- Magmatic deposits: Metals concentrate during magma cooling

- Hydrothermal deposits: Hot fluids transport and deposit metals

- Sedimentary deposits: Water action accumulates metal particles

What Role Do Metal Deposits Play in Society?

In the industrial sector, metals form the cornerstone of numerous critical industries. Steel, as the primary material for modern construction and machinery manufacturing, underpins the rise of skyscrapers and the efficient operation of diverse mechanical equipment. Copper, valued for its exceptional conductivity, is extensively used in power transmission and the manufacturing of electronic devices, serving as a vital foundation for ensuring a reliable electricity supply and effective information communication in modern society. Aluminum, with its lightweight and corrosion-resistant properties, plays an irreplaceable role in aerospace, automotive manufacturing, and other fields, aiding humanity in realizing the dream of flight and facilitating convenient transportation.

Economically, the development and utilization of metal ore deposits profoundly impact national economic growth. On one hand, the metal mining industry generates substantial employment opportunities, requiring numerous professionals across every stage—from geological exploration and mining operations to mineral processing and metal smelting. On the other hand, trade in metal ore products constitutes a significant share of international commerce, generating considerable economic revenue and serving as a vital pillar of national economic development. For instance, as a major global iron ore exporter, Australia's iron ore export revenues make substantial contributions to its economic growth.

Gaining a deep understanding of metal ore deposit characteristics is crucial for the sustainable development of the mining industry, serving as the key to unlocking scientific progress in mining science. Accurately grasping the characteristics of metal ore deposits helps geological prospectors more precisely locate potential deposits across vast landscapes, enhancing exploration efficiency and reducing costs. By studying features such as deposit occurrence conditions, ore grade variation patterns, geological structures, and the physical and mechanical properties of ores and host rocks, mining engineers can develop more scientifically sound extraction plans, ensuring both safety and efficiency in mining operations. Furthermore, understanding the characteristics of metal ore deposits holds immeasurable significance for rationally planning the development and utilization of mineral resources, protecting the ecological environment, and safeguarding national resource security. It helps strike a balance between resource development and environmental protection, enabling the sustainable development of the mining industry.

What Are The Classifications of Metal Ore Deposits?

Metal ore deposits can be classified based on various criteria, including mineral composition, metal associations, industrial uses, and economic value. Below are the primary classification systems:

1. Classification by Mineral Composition

Metal ores are categorized by the dominant forms of their metallic minerals:

Native Metal Ores

Metals occur in their free elemental state.

Examples:

- Native gold (Au)– Highly valued for jewelry and finance.

- Native silver (Ag)– Used in coins, electronics, and photography.

Oxide Ores

Metals exist as oxides.

Examples:

- Hematite (Fe₂O₃)– Key iron ore for steel production.

- Pyrolusite (MnO₂)– Manganese source for alloys and batteries.

Sulfide Ores

Metals bond with sulfur, forming economically vital deposits.

Examples:

- Galena (PbS)– Primary lead ore for batteries and shielding.

- Chalcopyrite (CuFeS₂)– Major copper ore for electrical wiring.

2. Classification by Metal Associations

Ores are grouped by the number of dominant recoverable metals:

Single-Metal Ores

Contains one principal metal.

Example: Pure copper ores, simplifying extraction.

Polymetallic Ores

Host two or more economically significant metals.

Example: Lead-zinc ores require complex separation methods.

3. Classification by Industrial Use & Metal Properties

A. Ferrous Metal Ores

Used chiefly in steelmaking and alloys:

- Iron (Fe)– The backbone of steel (construction, machinery).

- Manganese (Mn)– Enhances steel strength and corrosion resistance.

- Chromium (Cr)– Critical for stainless steel production.

B. Non-Ferrous Metal Ores

Essential in the electrical, aerospace, and construction industries:

- Copper (Cu)– Conductivity makes it ideal for wiring.

- Aluminum (Al)– Lightweight; used in aircraft and packaging.

- Nickel (Ni)– Alloyed with steel for high-temperature resilience.

C. Rare & Rare Earth Metal Ores

Vital for high-tech applications despite low crustal abundance:

- Lithium (Li)– Powers batteries in EVs and electronics.

- Rare Earth Elements (REEs: La, Ce, Nd, etc.)– Crucial for magnets (wind turbines), lasers, and phosphors.

D. Precious Metal Ores

High economic value due to scarcity and specialized uses:

- Gold (Au) & Silver (Ag)– Jewelry, electronics, and financial reserves.

- Platinum Group Metals (PGMs: Pt, Pd, etc.)– Catalysts (vehicle exhausts), fuel cells.

E. Radioactive Metal Ores

Fuel nuclear energy and medical technologies:

- Uranium (U)– Reactor fuel for electricity generation.

- Thorium (Th)– Emerging alternative nuclear fuel.

F. Dispersed Element Ores

Trace metals recovered as by-products from other ores:

- Germanium (Ge)– Fiber optics and infrared optics.

- Indium (In)– Thin-film solar panels and LCD screens.

Key Takeaways

| Classification Basis | Examples | Economic Significance |

| Native Metal Ores | Au, Ag | High-purity metals, low processing |

| Sulfide Ores | CuFeS₂, PbS | Major sources of Cu, Pb, Zn |

| Polymetallic Ores | Pb-Zn-Cu complexes | Higher value but complex extraction |

| Rare Earth Ores | Monazite (REE-bearing) | Tech-driven demand (magnets, EVs) |

| Precious Metal Ores | Au-bearing quartz veins | Reserve assets, advanced industry |

Understanding these classifications helps optimize mining strategies, metallurgical processes, and market positioning. We will introduce the details on the extraction methods for specific ore types.

What Are The Methods For Extracting Metal Ores?

Here’s a detailed breakdown of extraction methods for key ore types, tailored to their mineralogy and economic value:

1. Native Metal Ores (Au, Ag, Pt)

Extraction Method:Gravity Separation + Cyanidation/Amalgamation

For Coarse Gold (>100 µm):

- Gravity Concentration:

Knelson Centrifuge or Shaking Tables recover free gold (60–80% recovery).

Slurry → Concentrate (50–300 g/t Au) → Smelting (doré bars). - Amalgamation (Historical):

Mercury-coated plates capture gold (rarely used due to toxicity).

For Fine Gold (<100 µm):

- Cyanide Leaching (NaCN):

Crush/grind → Agitation tanks (pH 10–11, 0.05% NaCN) → Zn-dust precipitation→ Electrowinning.

Heap Leaching (low-grade ores): Ore stacked → cyanide drip (60–75% recovery).

2. Oxide Ores (Fe₂O₃, MnO₂, Al₂O₃)

A. Iron Ore (Hematite/Magnetite):

- Magnetic Separation (Magnetite):

Low-intensity drums pull magnetite (Fe₃O₄) from gangue (>95% recovery). - Flotation (Hematite):

Reverse flotation: Silica removed via amine collectors (pH 10–11).

B. Manganese Ore (Pyrolusite):

- Reduction Roasting + Leaching:

Rotary kiln (800°C, CO gas)→ MnO₂ → MnSO₄ (sulfuric acid leach).

C. Bauxite (Al₂O₃):

- Bayer Process:

Digestion: NaOH (140–300°C) dissolves Al₂O₃ → precipitate Al(OH)₃ → calcine to alumina.

3. Sulfide Ores (CuFeS₂, PbS, ZnS)

A. Copper (Chalcopyrite):

- Froth Flotation:

Collectors: Xanthates (pH 9–11) → Concentrate (20–30% Cu). - Pyrometallurgy:

Smelting: Matte (40% Cu) → Converters → Blister Cu (99%) → Electrorefining (99.99%). - Hydrometallurgy (Low-grade):

Heap Leaching (H₂SO₄ + bacteria)→ SX-EW (electrowinning).

B. Lead-Zinc Ores (Galena+Sphalerite):

- Differential Flotation:

Pb Circuit: Depress Zn (NaCN/lime) → Float PbS (xanthate).

Zn Circuit: Activate ZnS (CuSO₄) → Float (dithiophosphate). - Smelting:

Pb: Sinter plant → blast furnace → refining (97% Pb).

4. Rare Earth Ores (Monazite, Bastnäsite)

Extraction Method: Acid/Alkali Leaching + Solvent Extraction

- Crack REE Minerals:

Sulfuric Acid Bake (500°C)or NaOH Digestion (140°C). - Separation:

Solvent Extraction (D2EHPA/PC88A)→ Strip with HCl.

Precipitation → Oxalates/chlorides → Calcination (9% REO).

Key Challenge: Thorium/uranium removal (radiation control).

5. Radioactive Ores (Uraninite, Pitchblende)

Extraction Method: Acid/Alkali Leaching → Ion Exchange/Solvent Extraction

- Milling: Grind to –200 mesh → sulfuric acid leach (pH 1.5–2.0, H₂O₂ oxidant).

- Recovery:

Ion Exchange (Resin columns)or SX (Amine extractants) → Yellowcake (U₃O₈).

6. Placer Deposits (Alluvial Au, Sn, Diamonds)

Extraction Method: Gravity + Magnetic Separation

- Sluice Boxes/Jigs: Capture heavy minerals (Au, cassiterite).

- Spiral Concentrators: Upgrade titanium/zircon sands.

- Final Recovery:

Electrostatic/Magnetic Separation(e.g., ilmenite vs. rutile).

7. Complex Polymetallic Ores (e.g., Cu-Pb-Zn-Ag)

Extraction Method: Sequential Selective Flotation

- Cu-Pb Bulk Float: Depress Zn (NaCN + ZnSO₄).

- Cu-Pb Separation:

Depress Pb (CrO₃)→ Float Cu. - Zn Float: Activate with CuSO₄ → xanthate.

- Byproduct Recovery:

Ag: Follows Cu/Pb concentrates → cyanide leach.

Technical Comparison: Key Parameters

| Ore Type | Optimal Extraction | Recovery (%) | Key Challenge |

| Native Au | Gravity → Cyanidation | 85–95 | Fine gold loss to slimes |

| Chalcopyrite | Flotation → Smelting | 80–90 | Low-grade ore economics |

| REE Ores | Acid Bake → SX | 60–75 | Thorium disposal |

| Uranium | Acid Leach → IX/SX | 70–85 | Radionuclide handling |

| Placer Au | Sluices → Centrifuges | 90–98 | Clay-bound gold |

Emerging Trends

- Bioleaching: Bacteria (e.g., Acidithiobacillus) for Cu/As ores.

- Hybrid Flotation-Leach: For refractory Au/As ores (POX/HNO₃ pretreatment).

- AI-Optimized Sorting: XRT sensors reject waste rock pre-milling (20% energy savings).

Would you like process flow diagrams or cost analyses for specific methods? If yes, you can contact us!

As we've explored, metal deposits represent far more than geological curiosities—they're the foundation stones of human progress. From the iron framing our cities to the rare earths powering our smartphones, these concentrated gifts of nature demand both reverence and responsible stewardship. Understanding their formation, classification, and extraction isn't just academic; it's essential for meeting global demand while minimizing environmental impact. Whether you're an industry professional, student, or simply curious about Earth's metallic resources, appreciating this complex relationship between geology and human ingenuity is the first step toward sustainable resource management. The future of mining lies in balancing technological innovation with ecological wisdom—and that journey begins with knowledge.