Tin is a critical non-ferrous metal with widespread industrial applications. Did you know that 80% of the world's tin comes from alluvial deposits? Alluvial tin deposits (also called placer or stream tin deposits) are a major source of tin, differing significantly from hard-rock (lode) tin mining. Understanding how to efficiently mine and process these resources can dramatically improve your recovery rates and operational efficiency. This article systematically explores the uses of tin and its primary tin-bearing ores. It focuses on alluvial tin mining methods and processing techniques, followed by key takeaways and industry trends.

What Are the Main Applications of Tin?

From your smartphone to food packaging, tin touches nearly every aspect of modern life - yet most people don't realize its importance.

Tin serves critical roles in solder production (50% of global use), tinplate manufacturing (17%), chemicals (10%), and various alloys like bronze and pewter. Its excellent corrosion resistance makes it ideal for food containers, while its low melting point perfects solders for electronics assembly. Recent battery technology developments continue expanding tin applications.

Major Tin Application Areas

1. Electronics (52% market share)

- Lead-free solders (Sn-Ag-Cu alloys)

- Printed circuit board connections

- Semiconductor packaging

2. Packaging (22%)

- Tinplate for food cans

- Aerosol containers

- Bottle caps

3. Industrial Alloys (18%)

| Alloy | Composition | Uses |

| Bronze | Cu+Sn | Bearings, statues |

| Pewter | 85-99% Sn | Decorative items |

| Babbitt | Sn+Sb+Cu | Engine bearings |

4. Emerging Applications (8%)

- Lithium-ion battery components

- Solar cell technologies

- Smart glass coatings

Tin is mainly used in the production of solder, tinplate (tinplate), bronze alloy, etc. China's tin resource reserves and output are among the highest in the world.

What Are the Main Tin-Containing Ores?

Not all tin ores are created equal. Knowing which types contain economic concentrations can save years of unproductive exploration.

Cassiterite (SnO₂) accounts for over 90% of commercially mined tin, with stannite (Cu₂FeSnS₄) being the only other mineral of economic significance. While primary hard rock deposits exist, alluvial placer deposits containing cassiterite particles produce most of the world's tin due to easier processing and higher grades (0.01-1% Sn vs 0.1-2% in hard rock).

Tin Ore Types Comparison

1. Primary Deposits

- Found in granite-related hydrothermal veins

- Require costly underground mining

- Typical grades: 0.1-2% Sn

- Major locations: Bolivia, China

2. Alluvial Placer Deposits

- Formed by weathering and river transport

- Allow low-cost surface mining

- Grade range: 0.01-1% Sn

- Major locations: Indonesia, Malaysia

3. Characteristics of Economic Alluvial Tin

- Particle size: 0.1-5mm (ideal for gravity separation)

- Specific gravity: Cassiterite 6.8-7.1 g/cm³ (easily separable)

- Liberation size: Typically >100 mesh

- Common associated minerals:Quartz, Ilmenite, Zircon

How is Alluvial Tin Ore Mined?

Modern alluvial tin mining has evolved from simple panning to sophisticated operations moving thousands of tons daily, but which methods work best?

Alluvial tin mining primarily uses bucket-line dredges (floating factories processing 1,500+ tons/hour) and hydraulic mining systems. Bucket dredges suit deep deposits (>5m) with consistent grades, while hydraulic methods with gravel pumps dominate shallow (<5m) or discontinuous deposits. Proper method selection can reduce operating costs by 30-40% compared to inappropriate approaches.

Alluvial Tin Mining Methods Comparison

1. Bucket-Line Dredging

- Capacity: 50-2,000 m³/hr

- Depth: 5-50 meters

- Recovery: 80-90%

- Advantages:Continuous operation; Built-in processing plant

- Disadvantages:High capital cost (>$20M); Immobile once installed

2. Hydraulic Mining

- Water usage: 3-5 m³/ton

- Grade requirement: >0.02% Sn

- Typical setup:Monitor cannons; Gravel pumps (4-10"); Sluice boxes

3. Small-Scale Methods

- Panning (0.5-2 kg/hr)

- Rocker boxes (100-300 kg/hr)

- Jigs (1-5 ton/hr)

4. Environmental Considerations

- Soil erosion control

- Water recycling systems

- Revegetation programs

What Methods Are Used in Alluvial Tin Beneficiation?

Separating tiny cassiterite grains from tons of sand seems impossible - until you understand these proven gravity methods that achieve 60-95% recovery rates.

Alluvial tin beneficiation mainly uses gravity separation - jigs recover coarse cassiterite (+1mm), spirals capture medium sizes (1-0.1mm), and shaking tables concentrate fine particles (-0.1mm). Modern plants combine these with electronic sorting and flotation for optimal recovery. A well-designed flowsheet typically achieves 60-85% tin recovery at grades of 40-70% SnO₂.

Detailed Beneficiation Process

1. Primary Concentration

- Screening: Remove +5mm waste

- Scrubbing: Break clay clusters

- Roughing: Jigs (primary recovery); Spiral concentrators

- Middlings treatment: Re-cleaning spirals

2. Secondary Concentration

- Shaking tables (3 stages common): Primary table: 60% recovery; Secondary: +20% recovery; Tertiary: +5% recovery

- High-G-Force concentrators

3. Final Upgrading

- Magnetic separation (remove iron)

- Electrostatic separation

- Drying and packaging

Equipment Specifications

- Jigs: 2-5 ton/hr/m² capacity

- Spiral concentrators: 1-3 ton/hr

- Shaking tables: 0.5-1.5 ton/hr

Cost Factors

- Water consumption: 5-10 m³/ton

- Power requirement: 8-15 kWh/ton

- Labor: 1 worker/50 tons/day

Alluvial Tin Ore Beneficiation Example

Alluvial tin ore dressing

Characteristics of mineral processing

- The useful minerals in the original ore have basically been separated into monomers, and generally, no crushing and grinding are required.

- The mined sand ore is first screened to remove the gravel without minerals, and the ore with a lot of mud is desludged before being sent for sorting.

- The content of high-density minerals in sand ore is generally low, so the first roughing is typically carried out using equipment with a large processing capacity. Commonly used equipment includes: large jigs, cone concentrators, and coarse particle chutes.

Concentration process

- The coarse concentrate after roughing is sent to the selection workshop or central selection plant for processing.

- The concentration plant is equipped with equipment such as gravity separation, magnetic separation, flotation, and electrostatic separation, which can separate single mineral concentrates.

Natural Accumulation Residual Slope Tin Ore Dressing

Ore characteristics

- Generally, the tin content is 0.3%~0.5%.

- The ore has a large mud content and fine particle size, of which the -0.01 mm particle size content is about 50%, and the tin grade is only 0.041%, which can be removed as the final tailings before selection.

Ore preparation system: including ore washing, crushing, screening, grading, and desludging operations.

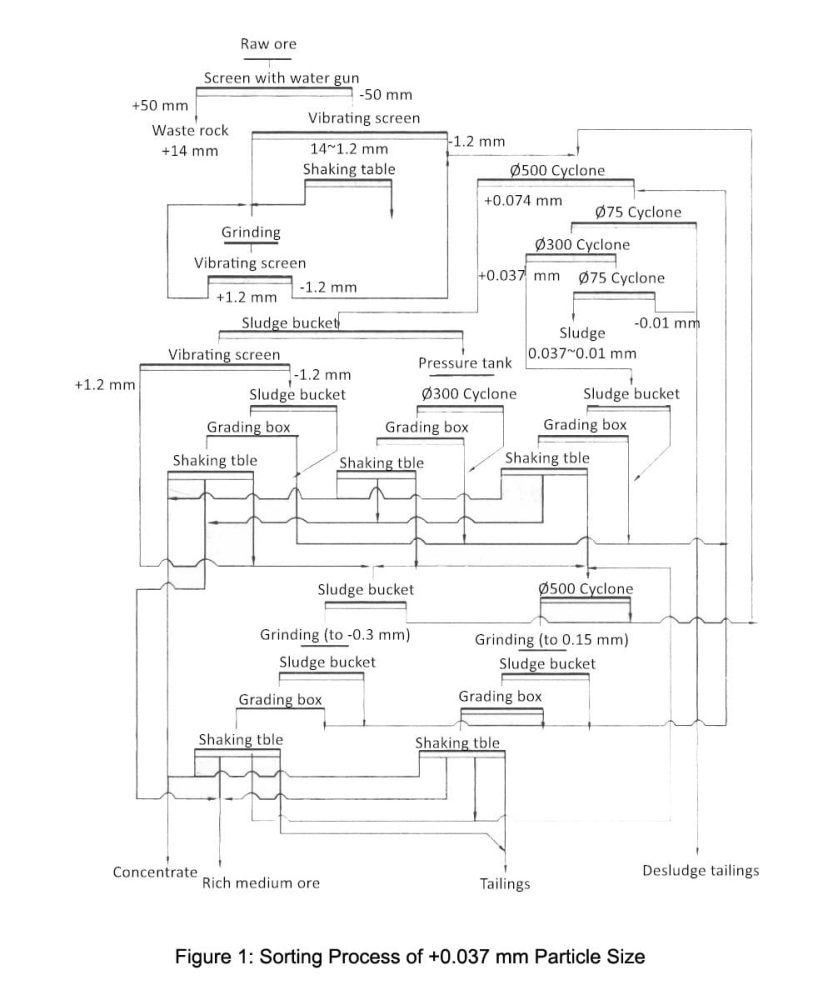

(1) Sorting process of +0.037 mm particle size

The full shaking table sorting process (as shown in Figure 1) is adopted, which mainly includes: 3-stage grinding, 3-stage sorting, concentrated pre-washing of secondary concentrate, regrinding and re-selection of medium ore, and separate overflow treatment.

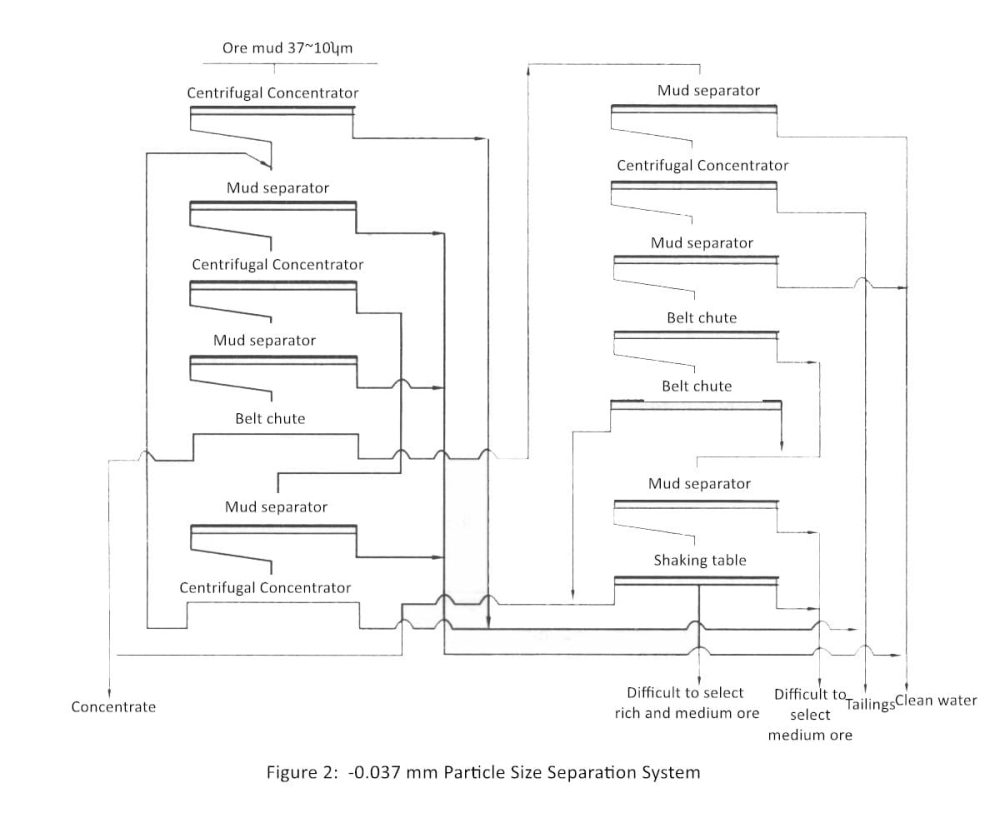

(2) -0.037 mm particle size separation system

Including: centrifugal concentrator roughing, belt chute concentrating, grooved ore sludge shaking table, or multi-layer suspended ore sludge shaking table sweeping (as shown in Figure 2)

Production indicators:

- Ore tin grade: 0.3%~0.53%

- Tin concentrate grade: 45%~50%

- Total tin recovery rate: 53%~57% (of which the tin recovery rate of the ore sludge system accounts for 13%)

Placer tin ore is usually directly separated by gravity separation because the minerals have been separated into monomers. The process is simple, and the cost is low. Residual slope deposit placer tin ore has high mud content and fine particle size, so it needs multi-stage grinding + classification desludging, and a combination of shaking table + centrifugal concentrator is used to improve the recovery rate. Tin ore beneficiation technology is mature, but the recovery of low-grade ore mud is still the focus of optimization.

Summary

Alluvial tin remains the world's most important tin source due to lower extraction costs than hard rock mining. Successful operations combine appropriate mining methods (dredges/hydraulic) with optimized gravity separation circuits. Modern plants achieve 60-85% recovery rates through staged processing - initial screening and jigging, followed by multi-stage tabling. With tin demand growing 2-4% annually in electronics and battery sectors, efficient alluvial tin operations remain highly profitable.