According to the research and forecast report on the status quo of the copper mine industry, the investment in domestic copper mine exploration has decreased and the import dependence is high. Copper concentrates are mainly used in real estate, power electronics, transportation, consumer and industrial equipment and other fields. It ranks second in the consumption of non-ferrous metal materials in my country, and the exploration and exploitation of resources need to be strengthened. With the continuous mining of ore, the properties of ore will also change. To ensure the mineral processing index and improve the economic benefits of the mine, it is also necessary to optimize the copper beneficiation process. Most of the copper oxide needs to be vulcanized by chemicals, and then beneficiated. Compared with copper sulfide, the selection is more complicated and more agents are used.

Properties of Copper Ore

1. In terms of ore composition, copper sulfide ore is relatively complex, while the composition of copper oxide ore is relatively simple;

2. In terms of price, copper oxide ore is relatively cheap, but the cost of beneficiation agents is high;

3. The oxidation rate of ores is different, the oxidation rate of sulfide ore is lower than 30%, and the oxidation rate of oxidized ore is higher than 30%;

4. The amount of copper oxide ore is small, and the amount of copper sulfide ore is large. More than 80% of the world's copper is refined from copper sulfide ore, but the copper content is very low, generally around 2%-3%.

Copper oxide:

The most common copper oxide minerals are malachite and azurite, followed by chrysocolla and cuprite, although copper sulfate and other soluble salts are sometimes encountered.

Copper sulfide:

Copper-sulfur ore is a common ore type in copper sulfide ore, and chalcopyrite and pyrite are typical sulfide minerals in copper-sulfur ore. Flotation is an important processing link to obtain metallic copper and sulfur raw materials from such ores.

Copper Beneficiation Process

Copper oxide ore beneficiation process

1. Grinding-flotation process: This process is suitable for processing copper minerals with coarse and uniform particle size, loose combination of copper minerals and gangue, and smooth and flat contact edges. Usually, the raw ore is ground to -200 mesh, accounting for 50-60%, and the copper minerals can be dissociated as monomers. This flotation process is simple and the cost of beneficiation is low, and it is mostly used in small and medium-sized copper processing plants.

2. One-stage grinding-flotation-coarse concentrate regrinding process: This process flow is most suitable for processing single sulfide ore or copper-molybdenum ore of porphyry copper ore. Due to the regrinding of coarse concentrate, the particle size is finer, the monomer dissociation degree of copper mineral, gangue mineral and pyrite is better, and the quality of flotation concentrate is also higher. This technological process can enable the copper ore concentrator to obtain better economic benefits when the raw ore grade is low and the processing capacity is large.

3. Two-stage grinding-two-stage (or one-stage) flotation process: For copper ore with uneven distribution of thickness, to dissociate most of the copper mineral monomers, it is necessary to grind the ore to -200 mesh, accounting for 80%, or even finer. At this time, the two-stage grinding is better than the one-stage grinding in terms of grinding efficiency and preventing copper minerals from being over-crushed. The grade of this part of the concentrate is generally high, and it can be directly used as the concentrate, or enter the final selection, or be combined with the concentrate obtained from the two-stage grinding and flotation. The grinding cost of this technological process is relatively high, and the equipment configuration and production operation are relatively complicated, so it is mostly used in large and medium-sized copper concentrators.

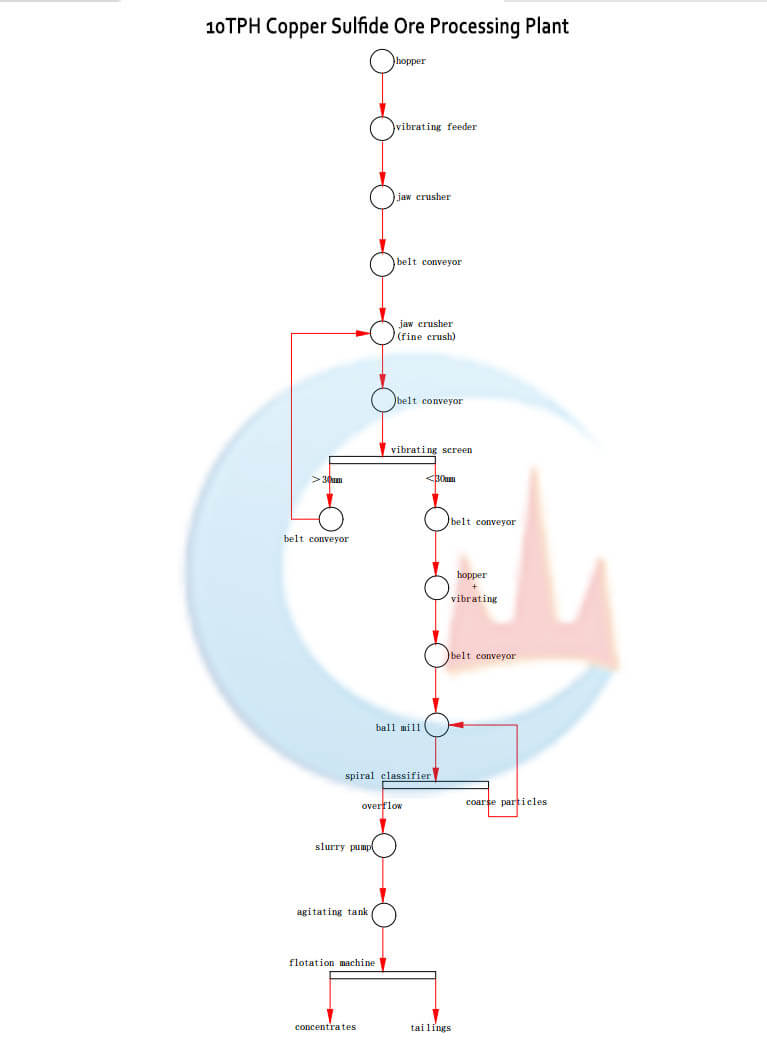

Copper sulfide ore beneficiation process

The separation of copper oxide ore is more complicated, and the comprehensive mineral processing cost is high. In contrast, separating copper sulfide ore is easier, and the comprehensive cost of mineral processing is lower. Generally, copper sulfide ore adopts flotation machine, which has simple process, low cost and good recovery effect.

Among them, the above copper oxide ore beneficiation process is also applicable to separating copper sulfide ore, and the process flow is formulated according to the properties of copper minerals.

- Priority flotation process: Distribution priority flotation is suitable for more complex copper sulfide ores, and its copper ores are of various types, mainly azurite and arsenic copper ore. Since various copper ores have different floating speeds, copper minerals that are easy to float can be roughly selected first.

- Reverse flotation process: The reverse flotation process of copper ore needs to go through the process of crushing and screening - grinding and classification - coarse, fine and scavenging - concentration and dehydration.

- Mixed flotation process: copper ore mixed flotation process: grinding and classification - mixed concentrate obtained by mixed flotation - concentrate separation and rough concentration - concentration and dehydration. The mixed flotation process of copper ore is to flotation the copper concentrate and other minerals contained in the ore together to obtain a mixed concentrate, and then sort the mixed concentrate to finally obtain a copper concentrate.

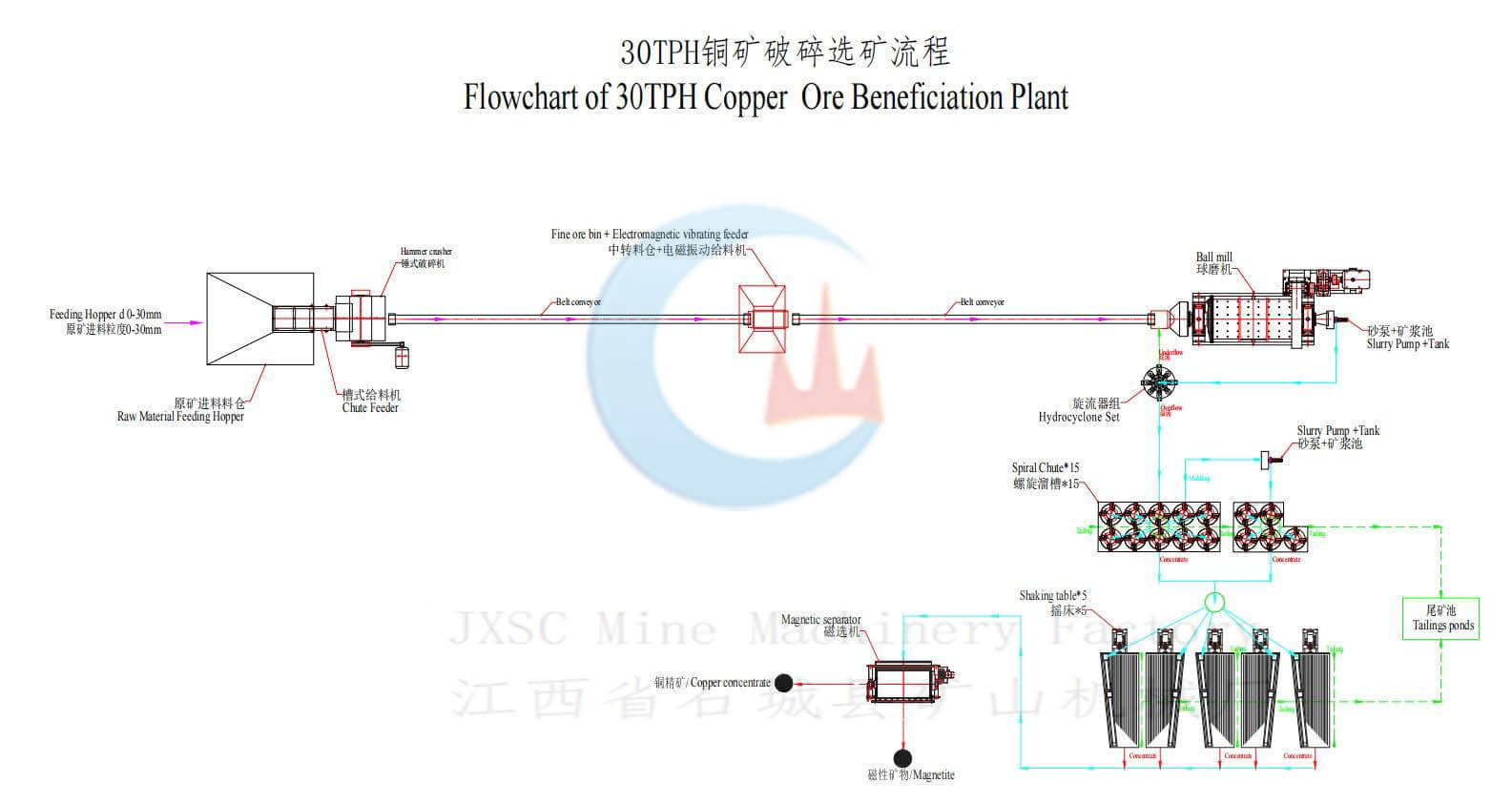

Copper Processing Plant

The above two types copper ore process and configured according to the actual situation. Our copper ore production line has the advantages of high efficiency, low energy, high processing capacity, and reasonable economy., the capital spent is reasonable, and the rate of return is efficient. The process is customizable, one link is linked to another, the steps are compact, and it has been tested and practiced many times. JXSC Mining Machinery can customize various types of ore processes and mining equipment for you, with 35+ mineral processing experience, safe and reliable, contact our professional engineers for consultation.