The magnetic separation process is mainly to carry out a three-stage magnetic separation treatment on the ore powder and then go through the wet material magnetic separation. The finished iron ore concentrate powder is obtained. Generally, the iron content of the ore is 35%. After magnetic separation by this method, the iron content of the iron concentrate powder can reach 68-70%.

In the combined process method, the utilization rate of ore can reach 90%, the water consumption in the process is less, water-saving, cost reduction, and pollution reduction. The magnetically selected dust is captured by the dust removal device, which will not cause air pollution. This method is a kind of creative process method with high production efficiency, good product quality, and no environmental pollution.

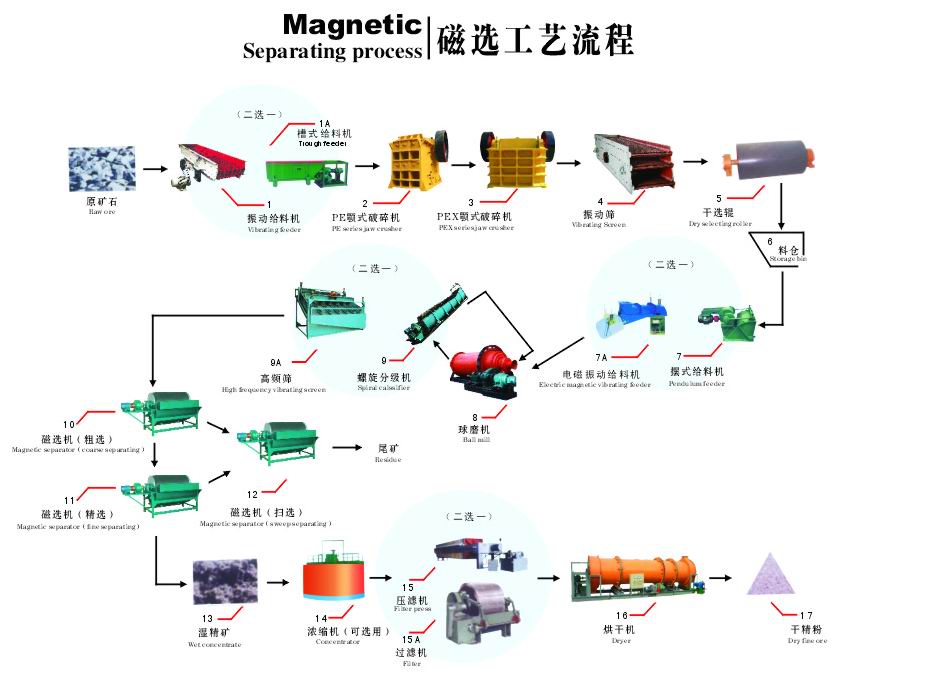

The process of the magnetic separation production line is rough as follows:

(Silo)—>Feeder—>Jaw Crusher—>Jaw Crusher—>Ball Mill—>Spiral Classifier—>Magnetic Separator pink). The machines in the middle can be connected by conveyors or conveyor belts.

The rough division principle of mineral magnetism

Iron-bearing ores have more or less certain magnetic properties. Before understanding the iron ore beneficiation process, let’s first understand the general division of mineral magnetic properties:

- Strong magnetic minerals

Weak magnetic separators with specific susceptibility greater than 3000×10-9m3/kg and magnetic field strength H=100-2000GS can be selected. Mainly include: magnetite, maghemite (r-hematite), titanomagnetite, pyrrhotite, zinc-iron spinel, most of these minerals belong to ferrimagnetic substances.

- Medium magnetic minerals

The specific magnetic susceptibility is between 600 and 3000×10-9m3/kg. Such minerals include ilmenite and pseudohematite. To select such minerals, a magnetic separator with a magnetic field strength of 2000-6000GS is required.

- Weak magnetic minerals

The specific magnetic susceptibility is between 15~600×10-9m3/kg, and the strong magnetic separator with the magnetic field strength of 6000~20000GS can be selected.

Causes of problems in the magnetic separation process

There are occasional problems in the operation of the magnetic separation process. The root causes of these problems are:

Too much ore feeding

Excessive ore feeding makes the sieve overloaded, unable to meet the requirements of the sieve’s working conditions, resulting in an excessively high content of qualified grades on the sieve. This is mainly because the high-frequency fine sieve manufacturer’s expectation of the high-frequency fine sieve production capacity is too high. The problem is exacerbated by feeding mines at or above the production plant’s nominal capacity;

The design of the feeding part is not reasonable

The unreasonable design of the feeding part will cause the feeding part to wear too fast, reducing the service life of the screen; and the material of the screen is not good enough.