With its unparalleled physical and chemical properties coupled with inherent scarcity, gold maintains indispensable roles across monetary reserves, industrial applications, and advanced manufacturing sectors. As technological advancements progress, gold's utility has evolved beyond traditional monetary and jewelry domains to become crucial in modern industries, including electronics, aerospace, instrumentation, synthetic fibers, chemical engineering, and national defense.

This article presents a systematic examination of the complete gold processing chain—from raw ore to final products. We will detail essential beneficiation and metallurgical techniques, including gravity separation, amalgamation, flotation, cyanidation, heap leaching, thiourea leaching, and carbon-in-pulp methods. Through this comprehensive overview, readers will gain complete insight into the sophisticated technologies powering gold extraction and refinement.

Global Gold Resources and Pre-Treatment Processes

The distribution of global gold resources remains highly uneven, with South Africa dominating as the world's largest producer, accounting for over 40% of total output. Historical production data reveals steady growth: global gold output rose from 53.2 million ounces in 1985 to 55.3 million in 1986, reaching 59.2 million ounces by 1987. Fluctuations in international gold prices directly influence production scales, as price surges typically incentivize expanded mining operations.

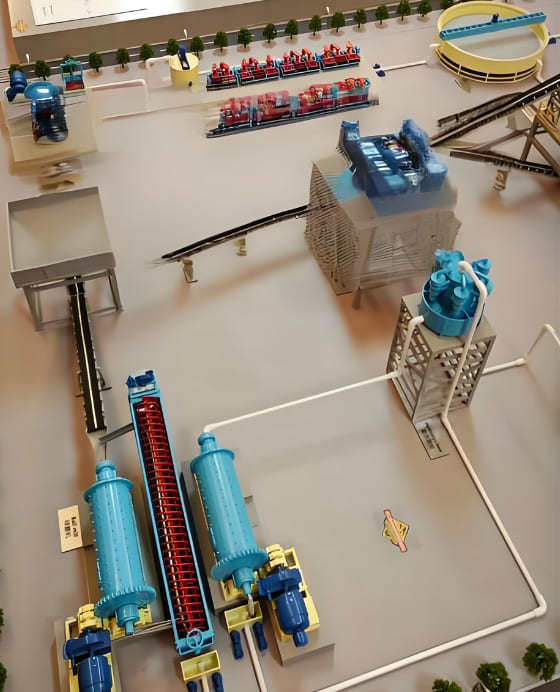

Ore Crushing and Grinding: Foundation of Gold Processing

As the critical first stage in gold extraction, pretreatment methods vary significantly depending on ore types (placer vs. lode deposits) and gold mineralization patterns. For hard rock ores, a multi-stage comminution process is essential:

- Size Reduction System

- Primary/coarse crushing

- Secondary/intermediate crushing

- Tertiary/fine crushing

- Particle Liberation

Ball/rod milling to achieve optimal grind sizes

Target fineness: 50-60% passing 250μm (60 mesh) to 100% passing 45μm (325 mesh)

Strategic placement of gravity separation equipment (e.g., jigs, shaking tables) within grinding circuits enables early-stage gold recovery—an operational philosophy known as "recover early, recover often." Field implementations at Shandong processing plants demonstrate that this approach effectively reduces tailings grade while boosting overall recovery rates by 2-5 percentage points.

Gold Ore Beneficiation Methods & Industrial Applications

Gravity Concentration

Gravity separation remains the most cost-effective method for recovering coarse free-milling gold, dominating placer gold processing while serving as auxiliary treatment in lode gold operations. This technique leverages gold's high density (19.32 g/cm³) versus gangue minerals (typically 2.7-3.0 g/cm³).

Key Gravity Equipment

- Sluice boxes: Low-cost, simple structure; ideal for coarse gold recovery (e.g., felt-lined sluices in China)

- Jig concentrators: High throughput; integrated into grinding circuits for liberated gold

- Shaking tables: Precision separation for cleaning circuits

- Hydrocyclones: Fine particle recovery (sub-100μm)

Innovations: South Africa developed advanced systems like Reichert cones and Johnson drums, while the USSR achieved success with short-cone hydrocyclones for low-grade fines. Chinese operations (e.g., Shandong) demonstrate 3-8% recovery boosts by implementing gravity pre-concentration in altered-rock gold circuits, simultaneously reducing tailings grade.

Amalgamation

This ancient technique exploits mercury's selective gold-wetting properties to form amalgam. Despite operational simplicity and low costs (still used in 25-30% of US lode gold plants), it faces critical challenges:

Environmental Risks:

- Toxic mercury vapors endanger workers

- Persistent ecosystem contamination

- Increasing Minamata Convention restrictions

Industry trends show replacement with cyanidation for gravity concentrates. The method's future hinges on breakthroughs in mercury containment technologies.

Froth Flotation

The dominant process for gold-sulfide ores (e.g., pyrite/arsenopyrite associations), flotation concentrates gold-bearing sulfides while rejecting >80% gangue, dramatically reducing downstream costs.

Critical Parameters

1. Reagent Scheme

Primary collectors: C2-C5 xanthates

Synergistic blends:

- Butyl xanthate: ammonium dibutyl dithiophosphate (2:1) for Au-pyrite

- Xanthate + diesel emulsification

- 2-Mercaptobenzothiazole + neutralized 31# collector

2. Process Design:

Typical "1 roughing-2 scavenging-3 cleaning" circuits

The practice of Suichang Gold Mine in Zhejiang Province shows that the gold and silver recovery rates increased by 7.11% and 10.52%, respectively by changing the single butyl xanthate to a mixture of butyl ammonium black medicine and butyl xanthate, and the concentrate grade was also significantly improved. New collectors such as alkyl isothiouronium salts (dosage is only 2-15 g/ton) have good selectivity for gold-bearing pyrite.

Gold Extraction Metallurgical Technologies

Cyanidation

Since its industrial adoption in the late 19th century, cyanidation has remained the dominant gold extraction process due to its maturity, cost efficiency, and high recovery rates. The process relies on gold dissolution in alkaline conditions via stable [Au(CN)₂]⁻ complexation.

Cyanidation Process Variations

- Gravity concentrate cyanidation – Targets enriched gravity separation products

- Gold concentrate cyanidation – Treats sulfide flotation concentrates (e.g., pyrite/arsenopyrite)

- Flotation tailings cyanidation – Recovers fine gold missed in flotation

- Sludge cyanidation – Processes gold-bearing residues from electrolysis/other methods

Key Advances

Multi-stage leaching:

- Mexico's Tayoltita plant (96% recovery via two-stage)

- Canada's Kemess plant (96.3% via three-stage)

Vortex reactors (Bell-style): Enhances mass transfer, reduces passive-film adhesion on gold

Pre-treatment: Roasting/bio-oxidation for refractory ores

Limitations: Poor efficacy on As/Sb/Se/Te-bearing ores, high toxicity risks, and interference from cyanides (e.g., pyrrhotite, chalcocite) that overconsume cyanide/O₂.

Heap Leaching

Heap leaching economically treats low-grade ores (0.5–1.5 g/t Au). By stacking ore and irrigating with a cyanide solution, gold dissolves and is recovered from the pregnant solution (30–90% recovery, ore-dependent).

Critical Steps

Site prep: HDPE-lined pads for seepage control

Ore conditioning: Crushing (<25 mm), agglomeration to mitigate fines clogging

Irrigation: Uniform cyanide spray (0.05–0.1% NaCN, pH 10–11)

Recovery: Carbon adsorption (CIP) or zinc precipitation

Industry Adoption

US: Pioneered in the 1970s; now a global standard for marginal ores

China: Trials since 1979 (e.g., Hushan Mine), limited by scale and mechanization costs

Constraints: High sulfide/clay/carbon content harms permeability. B.M. Clem mandates heap-leachability tests pre-deployment.

Thiourea (Thiourea Leaching)

A promising cyanide alternative, thiourea ([CS(NH₂)₂]) offers:

- Non-toxicity

- 10–12× faster kinetics than cyanide

- Superior silver dissolution (10.8× faster)

Typical Leaching System

- Thiourea: 1%

- H₂SO₄: 6.5%

- Oxidant (Fe³⁺): 0.1%

Applications

USA: 90% recovery on Carlin-type refractory ores

China: Changchun Gold Research Institute’s 10 tpd pilot plant

Challenges: High reagent consumption (thiourea oxidation), acidic corrosion, and precise control requirements hinder large-scale use.

Carbon-in-Pulp/Leach (CIP/CIL)

Developed in the 1970s, CIP/CIL adsorbs gold-cyanide complexes directly from slurry, bypassing solid-liquid separation. The first commercial CIP plant was launched in 1977 (Homestake Mine, USA); >40 operate globally today.

Core Process

Adsorption: 5–8 agitated tanks (countercurrent carbon/slurry flow)

Carbon: 8–20 mesh coconut shell; ~9.5 g/L tank concentration

Gold recovery: Elution (hot NaOH/NaCN) → electrowinning

Carbon regeneration: Acid wash → thermal reactivation

Variants

CIL (Carbon-in-Leach): Simultaneous leaching/adsorption (CAPEX savings ~$200k for 100 ktpd plants)

Magnetic-Carbon: Magnetic separation reduces screening losses

China’s Case: Successful deployments at Linghu and Chiweigou mines. R&D focuses on novel adsorbents (e.g., PAN-based carbon fibers, woven carbon cloth) to boost efficiency and attrition resistance.

Emerging Technologies & Future Outlook

Beyond conventional methods, the gold extraction sector is witnessing groundbreaking innovations:

1. Alternative Lixiviants

Chlorination: Cl₂-based oxidative leaching

Polysulfide-amine: Effective for complex Sb/As-bearing ores

Thiosulfate: Low sensitivity to copper interference

Organic nitriles: Eco-friendly reagents

2. Specialized Processes

Bioleaching: Acidophilic bacteria pre-treat refractory ores

Resin-in-Pulp (RIP): Ion-exchange resins replacing activated carbon

Solvent extraction: High-purity gold isolation

High-pressure cyanidation: Intensified leaching kinetics

3. Resource Expansion

Seawater extraction: Experimental stage (sub-ppb concentrations)

"Three residues" recycling: Au/Ag recovery from sulfuric/copper/zinc slag

E-waste processing: Urban mining of electronic scrap

4. Equipment Innovations

Enhanced gravity separators: Centrifugal concentrators

Microwave-assisted leaching: Accelerated reaction rates

Automated control systems: AI-driven process optimization

5. The Path Forward

Gold extraction technology is evolving along four key trajectories:

Greening the Industry

Non-toxic reagents, reduced footprints, closed-loop water systems

Pushing Efficiency Frontiers

Raising recovery rates, exploiting sub-0.3 g/t deposits

Holistic Resource Utilization

Co-recovery of associated metals (Cu, Ag, PGEs)

Digital Transformation

Machine learning for real-time process control, predictive maintenance

Conclusion

Modern gold metallurgy blends time-tested methods (gravity/cyanidation/CIP) with advanced hybrid flowsheets like:

"Gravity → Flotation → Cyanidation" for free-milling ores

"Flotation → Roasting → Bio-oxidation → Leaching" for refractory types

As environmental mandates tighten, cyanide-free extraction (thiosulfate/thiourea) and biometallurgy will gain prominence. Concurrently, Industry 4.0 technologies (IoT sensors, digital twins) will drive operational excellence, boosting recoveries while slashing energy/water use.

Through continuous innovation, the gold industry is poised to sustainably meet global demand while minimizing its ecological impact, ensuring the long-term viability of this critical resource.