Tailings are "wastes" discharged by mining enterprises under certain technical and economic conditions. The development and utilization of a large number of tailings accumulated over a long period of time can effectively alleviate the pressure on resources and the environment. In production, the properties of tailings ore are different, and the mineral composition, specific gravity, concentration, particle size and distribution are also different. The tailings after dry discharge can be reused, such as filling goaf, building materials, road construction, fertilizer and so on. To achieve "turning waste into treasure", a feasible tailings processing plant must be adopted to comprehensively recycle and reuse it.

Why use the tailings treatment process?

1. The dry discharge of tailings can solve the environmental pollution and potential safety hazards caused by the accumulation of traditional tailings, such as tailings dam failure and land occupation;

2. Less investment and great benefit: On the one hand, it greatly saves the company's safety, ecological environment management funds, energy conservation and emission reduction and tailings pond maintenance costs.

3. The valuable components in the tailings can be recovered to improve the economic benefits of the enterprise.

Dry Tailings Process

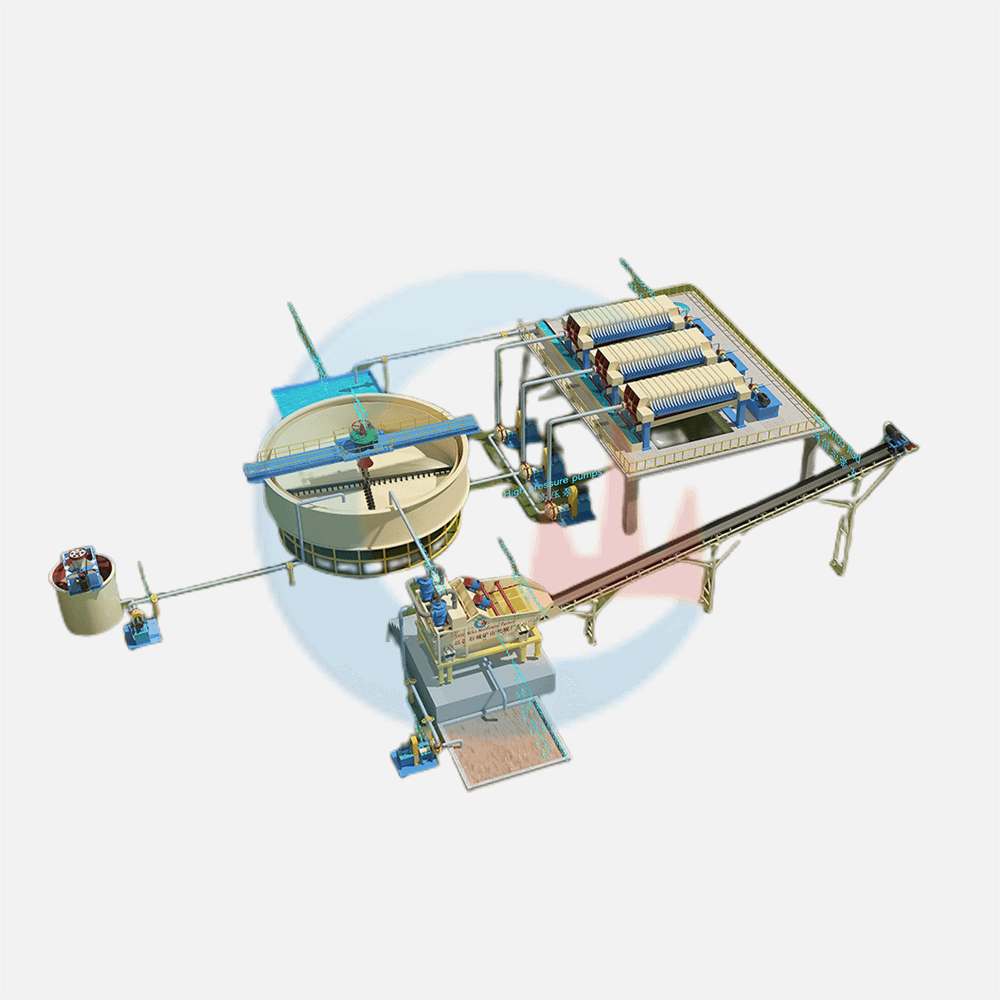

Dry tailings discharge is a new type of tailings treatment process. It refers to the method of concentrating and dewatering the tailings slurry output from the beneficiation process to form slag with low water content, precipitation solidification and site accumulation, and transporting the slag to a fixed location for dry heaping. The main process methods are: concentration equipment + dewatering equipment + conveying equipment.

Generally, the tailings dry discharge process system is mainly composed of a slurry pump, a hydrocyclone, a high-efficiency reformed thickener, a high-frequency and high-efficiency dewatering screen, a box filter press, and a slurry conveying device.

The tailings are transported to the hydrocyclone by the slurry pump for concentration and classification. The sand from the hydrocyclone enters the high-frequency high-efficiency dewatering screen for dehydration treatment, and the overflow enters the high-efficiency reformed thickener for concentration treatment. The coarse-grained tailings treated by high-frequency and high-efficiency dewatering screens are transported to the stockyard for storage by belt conveyors. Among them, the tailings that have been concentrated and processed by the high-efficiency reformed thickener are transported by the slurry pump to the chamber filter press for filtration treatment, and the filter cake of the filter press is self-unloaded to the belt conveyor, and the fine tailings are transported to stockyard storage.

The dry tailings discharge process can relieve the pressure on the storage capacity of the tailings pond, reduce the potential safety hazards of the tailings pond, and increase the means of reuse of the tailings. It is a tailings treatment process for realizing green environmental protection mines.

Advantages of Dry Tailings Process

1. Small footprint and low follow-up production costs

Dry discharge after concentration and dehydration of tailings can not only save the construction cost and routine maintenance cost of traditional tailings pond, but also make full use of backwater, greatly save the floor space, and save the reclamation after the tailings pond is closed. governance costs.

2. High safety and environment friendly

The dry tailings discharge process avoids the risks of dam failure, flooding and dam collapse in tailings ponds, eliminates potential safety hazards, saves safety investment, and reduces environmental pollution.

3. Less investment, great social and economic benefits

In general, the production cost of dry tailings discharge is about 3%-10% higher than that of wet tailings discharge. Saving about 30%, and the amount of tailings deposited on the same area of land will increase by about 20%-30%, correspondingly reducing the floor space. In addition, when the tailings are comprehensively recycled in the later stage, the dry-stacked tailings are easier to recover and utilize than the tailings slurry stored in the tailings pond. social and economic benefits.

Comprehensive Utilization of Tailings

- Sand and gravel aggregates are the most used, indispensable and irreplaceable basic materials for infrastructure projects such as buildings, roads and bridges. However, sand and gravel aggregates are non-renewable resources, and the mining for thousands of years has caused great damage to the earth's environment. In my country's metal and non-metal mine industry, in the long-term mining and production process, mines produce a large amount of waste rock and tailings, and the use of these tailings resources can completely replace or partially replace sand and gravel aggregates.

- Concrete fine aggregate: The use of tailings as fine aggregate for concrete should also consider the same requirements for coarse and medium aggregates. Generally speaking, tailing sand is better than sea sand, because sea sand often contains salt and chloride ions, which is easy to corrode steel bars, and the surface of tailings is rough and angular, which can increase the strength of concrete. However, to use the tailings as fine aggregate, a certain particle size is required. When the particle size does not meet the requirements, the tailings need to be screened. Because the coarse sand makes the concrete drier, the viscosity decreases, and the workability is not good; the ultra-fine sand not only makes the concrete easy to segregate, but also requires a large amount of water, thereby increasing the amount of cement.

- Cement mix: Adding an appropriate amount of mixed materials to cement can not only improve some properties of cement, but also save the consumption of basic materials. Mixed materials are divided into two types: filling and active. At present, blast furnace slag and fly ash have become commonly used cement active admixture materials. In fact some tailings are also suitable for use as mixed materials, such as tailings from vanadium ilmenite deposits in amphibole. In addition, waste rock (or tailings) with higher content of amorphous substances, such as vitreous volcanic rock, tuff, pumice, etc., can also be used as active mixed materials.

- All kinds of stone bricks: In fact, many tailings can be used to make steam-cured bricks/autoclaved bricks, which are made by cementing the tailings with a certain gelling agent and then curing them with steam or even high-pressure steam.

With the release of the national "green mine" standard, the tailings dry discharge process has shown great advantages in terms of economy, environment and safety, and has become an important choice for current tailings treatment. Specific analysis of tailings particle size, concentration, composition, mud content, and comprehensive consideration of backwater quality requirements, tailings scale, investment budget, etc. Tailored and reasonable tailings processing equipment.