In mineral processing, the right grinding fineness can make or break your operation. Are you wondering what it is and how it affects your results? Let us explore the importance of grinding fineness in mineral processing.

Grinding fineness refers to the particle size of ground material in mineral processing. It significantly impacts the efficiency of mineral recovery and overall processing performance. By understanding how to measure, control, and optimize grinding fineness, you can substantially improve the outcomes of your mining operations.

Optimizing grinding fineness is an essential aspect of mineral processing. It involves understanding its definition, proper measurement techniques, and how to strike a balance for the best recovery rates. Let’s dive deeper into the topic and uncover its significance in the mining industry.

What is Grinding Fineness in Mineral Processing?

Grinding fineness is a crucial concept in mineral processing that determines the particle size and distribution of ground material. It is primarily assessed through particle size distribution to ensure the material achieves an ideal size for subsequent processing.

In mineral processing, grinding fineness is usually measured through various screening methods. The feedback from particle size distribution helps miners understand whether the grinding process meets expectations. Understanding this concept can lead to higher ore recovery rates and cost-effectiveness.

How to Measure Grinding Fineness?

To accurately measure grinding fineness, several effective methods can be employed:

| Method | Description |

| Screening Method | Utilizing screens of different mesh sizes to calculate the percentage of material passing through. |

| Laser Particle Sizing | Measuring particle size and distribution using laser diffraction technology. |

| Settling Method | Applying Stokes' Law to calculate the settling speed of particles in a liquid. |

Choosing the appropriate measurement method is essential to ensure the grinding process aligns with desired outcomes.

The Importance of Grinding Fineness in Mineral Processing

Grinding fineness plays a vital role in mineral processing. It influences several factors, including recovery efficiency and product quality.

1. Mineral Liberation: Unlocking Value

Controlled grinding liberates valuable minerals from the gangue matrix, enhancing their separation potential. However, over-grinding can generate excessive fines ("slimes"), which may entrain contaminants and reduce concentrate grade.

2. Flotation Performance: A Delicate Balance

Optimal Size Range: Flotation efficiency depends on particle size; excessively coarse particles may not attach to bubbles, while ultrafine particles (below 10 μm) can increase pulp viscosity and reduce selectivity.

Reagent Consumption: Fine grinding increases surface area, potentially requiring more reagents and raising costs.

3. Leaching Efficiency: Maximizing Surface Exposure

For heap or tank leaching, finer grinding improves mineral contact with leaching agents, enhancing metal dissolution rates. However, excessive fines can lead to percolation issues in heap leaching or filtration challenges in tank leaching.

Grinding is the most energy-intensive stage, accounting for 50-70% of the total processing energy. Higher grinding fineness improves the liberation of valuable minerals from the gangue. It allows for better separation in downstream processes. However, overly fine grinding can lead to increased energy consumption and extra wear on equipment, potentially raising operational costs. Balancing the right fineness is essential for maximizing profit.

What Factors Affect Grinding Fineness?

Achieving the optimal grinding fineness is critical for efficient mineral liberation and downstream separation. Multiple interacting factors influence the final particle size distribution, including ore characteristics, equipment selection, operational parameters, and process controls. Below are the 8 major factors that determine grinding fineness:

1. Ore Properties

Hardness & Abrasiveness (Bond Work Index):

- Harder ores (e.g., quartz) require longer grinding times or higher energy to achieve the target fineness.

- Abrasive minerals (e.g., magnetite) increase media wear, affecting grinding efficiency.

Mineral Liberation Size:

- Some ores (e.g., fine-grained sulfides) need ultra-fine grinding for effective liberation, while coarser ores (e.g., gold-bearing quartz) may only require moderate grinding.

Moisture & Clay Content:

- High-clay ores can cause ball coating, reducing grinding efficiency.

2. Grinding Circuit Design

Open vs. Closed Circuit Grinding:

- Open circuit: Simpler, but produces a wider particle size range with potential over-grinding.

- Closed circuit (with classifier): More controlled, recirculating coarse particles for regrinding.

Type of Grinding Mill:

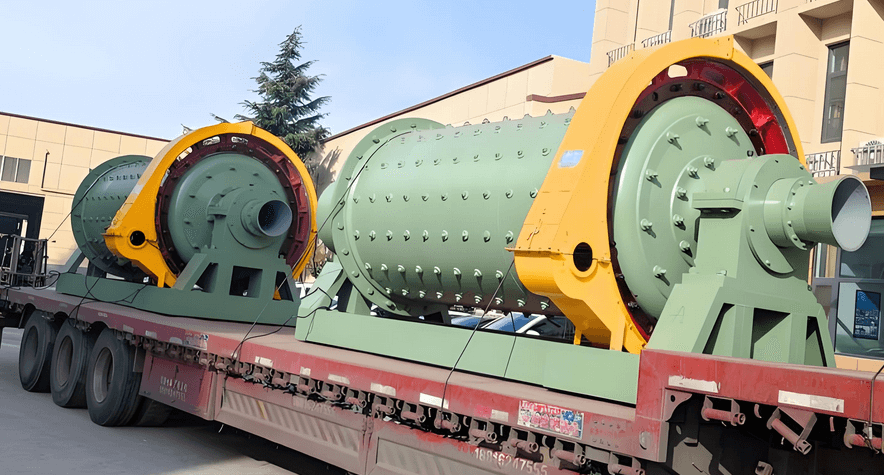

- Ball Mills: Best for medium-fine grinding (50–200 μm).

- Rod Mills: Coarse grinding (1–3 mm), minimizing slimes.

- SAG Mills: Handle large feed sizes (primary grinding).

- Stirred Mills (Vertimill, IsaMill): Ultra-fine grinding (<10 μm).

3. Mill Operating Parameters

Mill Speed:

- Critical speed%: Higher speeds increase impact grinding but may reduce control.

- Too slow → insufficient grinding; too fast → centrifuging.

Loading & Media Size:

- Ball charge (% of mill volume): Typically 30–45%.

- Ball size distribution: Larger balls break coarse particles, smaller balls refine fines.

- Optimal media shape: Worn balls reduce effectiveness.

Pulp Density & Rheology:

- Solid% in slurry: Too dense → cushioning effect (low impact); too dilute → poor grinding.

4. Classification Efficiency

Hydrocyclones / Screens:

- Poor classification → coarser return (over-grinding of fines).

- Cut size (D50): Must match target grind size.

Circulating Load:

- High recirculation (150–300%) improves efficiency but may increase energy consumption.

5. Feed Size Distribution

- Coarse feed requires a longer retention time in the mill.

- F80 (80% passing feed size) vs. P80 (80% passing product size): A larger F80→P80 difference means higher grinding effort.

6. Chemical & Reagent Effects (In Grinding-Flotation Circuits)

Pulp Chemistry: pH modifiers (lime, sulfuric acid) can affect steel wear and particle surface properties.

Grinding Aids (e.g., polyglycols): Reduce viscosity, improve energy efficiency.

Pulp Aeration: Oxidizing conditions can alter mineral surfaces before flotation.

7. Economic & Energy Constraints

Power Consumption vs. Recovery Trade-off:

- Finer grinding = higher energy cost (kWh/t), but better liberation.

- Optimal grind balances metallurgical recovery and operational cost.

Wear & Maintenance Costs:

- Liner/ball replacements, downtime impact economics.

8. Downstream Process Requirements

Flotation: Needs sufficient liberation but avoids ultra-fines.

Leaching: Finer grinding improves kinetics but may hinder percolation.

Gravity Separation (e.g., spirals, jigs): Prefers coarser feeds.

Is Finer Grinding Always Better in Mineral Processing?

No, grinding fineness should not be as fine as possible—excessive grinding often leads to diminishing returns and operational inefficiencies. While finer grinding improves mineral liberation, it must be balanced with energy costs, downstream process constraints, and economic viability.

Why Not Grind as Fine as Possible?

1. Energy Consumption & Cost

Grinding is the most energy-intensive stage (50–70% of total processing energy).

Bond’s Law: Energy required ∝ (1/√P80 - 1/√F80) → finer grinding exponentially increases power demand.

Example: Reducing grind size from 150 μm to 75 μm may double energy costs, but recovery may improve only marginally.

2. Over-Grinding Issues (Slimes Generation)

Ultra-fine particles (<10 μm) hinder separation processes:

- Flotation: Slimes coat bubbles, reducing selectivity & recovery.

- Gravity Separation (spirals, jigs): Fines report to tailings.

- Leaching: Fines can cause pore clogging(heap leaching) or filtration issues (tank leaching).

Slimes also increase reagent consumption (flotation collectors, depressants).

3. Mill Throughput & Efficiency Loss

Finer grinding reduces mill capacity (longer retention time needed).

Higher circulating loads increase classifier inefficiency, leading to regrinding of liberated particles.

4. Wear & Maintenance Costs

Media & liner wear increases with finer grinding due to higher impact & abrasion.

Operating costs rise due to frequent steel replacement and downtime.

When is Finer Grinding Beneficial?

Finer grinding may be justified in specific cases, such as:

- High-value, finely disseminated ores (e.g., refractory gold, rare earth minerals).

- Improved leaching kinetics (finer particles expose more surface to lixiviant).

- Liberation of micro-textured minerals (e.g., complex sulfide ores).

- Flotation of ultrafine particles (with specialized techniques like hydrophobic flocculation).

Optimal Grinding: Finding the Balance

The ideal grind size depends on:

- Target mineral liberation(measured via mineralogical analysis and liberation studies).

- Downstream process requirements (flotation, leaching, gravity separation).

- Economic optimization (energy cost vs. recovery trade-off).

Strategies to Avoid Over-Grinding

- Stage grinding: Separate coarse and fine grinding circuits.

- Advanced classification: Use hydrocyclones, sieve bends, or screeners to reduce fine recirculation.

- Grinding aids: Polymer-based additives improve efficiency.

- High-pressure grinding rolls (HPGR): Energy-efficient pre-grinding before ball milling.

While finer grinding improves liberation, it must be optimized—not maximized—based on metallurgical performance, energy economics, and process constraints. Over-grinding wastes energy, increases costs, and can even reduce recovery.

Conclusion

Grinding fineness is a critical factor in mineral processing that cannot be overlooked. It influences recovery rates, processing efficiency, and overall production costs. By comprehensively understanding its definition, measurement techniques, and influencing factors, you can make informed decisions that lead to better outcomes in your mining operations. Balancing fineness is essential, as finer is not always better. Embrace this knowledge to enhance your operational effectiveness.