Ilmenite is the world's primary titanium resource, accounting for over 90% of the total titanium ore supply. It is not only a key raw material for the production of titanium dioxide (a titanium dioxide pigment) but also a fundamental source of metallurgical-grade titanium products, such as titanium sponge and titanium alloys. Due to the continued growth in demand for titanium resources in sectors such as aerospace, military, chemical, and new energy, ilmenite has been designated a strategic mineral, attracting significant attention for its market value and process research.

However, ilmenite often coexists closely with magnetite, hematite, and gangue minerals, making separation challenging. How to effectively improve grades while maintaining recovery has always been a core concern for the industry. Among existing process systems, a combination of gravity separation and magnetic separation remains the most economical and universally applicable solution.

Global Distribution and Resource Characteristics of Ilmenite

As a strategic mineral resource, ilmenite exhibits significant regional variations in its global distribution. Different types of deposits have varying ore characteristics and development potential, profoundly impacting the global titanium supply chain.

1. Distribution of Major Resource Countries

Currently, the world's ilmenite resources are primarily distributed in Australia, South Africa, Nigeria, India, Mozambique, and Ukraine. China has also developed a large-scale ilmenite belt in the Panzhihua-Xiangxi region.

2. Resource Characteristics of Ilmenite

Most ilmenite ore bodies exhibit the following characteristics:

- Associated with iron minerals: often found in associated environments such as magnetite and hematite, the minerals are embedded in fine-grained deposits.

- Complex impurities: often containing elements such as vanadium and chromium, increasing the difficulty of metallurgy and beneficiation.

- Various resource types: both magmatic deposits and coastal placer deposits exist, resulting in significant variations in process flows.

These characteristics mean that ilmenite beneficiation processes are often difficult to implement with a one-size-fits-all approach and require flexible adjustments based on the ore's properties.

(1) Ilmenite coastal sand mines (easy to separate)

| Country | Major Deposits | TiO₂ Grade | Development Characteristics |

| Australia | Murray Basin, WIM 150 | 10-25% | The world's largest titanium sand mine, open-pit mining. |

| South Africa | Richards Bay, Zulti | 8-22% | High grade, associated with zircon and rutile. |

| India | Kerala, Tamil Nadu | 5-18% | Low stripping ratio, environmentally sensitive. |

| Sri Lanka | Pulmoddai | 10-16% | High purity, directly used for titanium dioxide production. |

Ilmenite coastal sand mines characteristics:

- High mineral dissociation degree, no need for crushing and grinding, can be enriched by gravity separation.

- Usually associated with high-priced minerals such as zircon and rutile, with high comprehensive returns.

- Low mining cost (<US$15/ton of raw ore)

Challenges of Ilmenite coastal sand mines:

- Subject to strict environmental regulations (e.g., Australia prohibits coastal mining).

- Prominent resource depletion problem (some mining areas in South Africa have a remaining mining life of <20 years)

(2) Ilmenite rock mines (difficult to separate)

| Country | Typical Deposits | TiO₂ Grade | Geological Characteristics |

| China | Panzhihua Vanadium-Titanium Magnetite | 5-12% | A super-large layered intrusion with Fe-Ti-V intergrowth. |

| Canada | Lac Tio, Allard Lake | 30-45% | The highest grade in the world, but located in the Arctic Circle. |

| Norway | Tellnes | 18-22% | Anorthosite-type, low in sulfur and phosphorus impurities. |

| Russia | Pudozhgorsky | 6-15% | Kola Peninsula, associated apatite. |

Ilmenite rock mines characteristics:

- Requires crushing and grinding to -0.2mmfor separation, resulting in high energy consumption (>35kWh/t);

- Often closely associated with magnetite and olivine, requiring a multi-stage magnetic separation-flotation process;

- Mining of ultra-high-grade deposits such as Lac Tio, Canada, is limited due to polar environments.

Difficulties in Ilmenite Separation & Process Selection

The core goal of ilmenite beneficiation is to effectively increase the TiO₂ grade while reducing the iron and impurity content. Unlike precious metals such as gold and tin, the industrial value of ilmenite depends on a large-scale, stable supply, making the economic and reliable process particularly important.

1. Key Technical Challenges in Ilmenite Beneficiation

The effectiveness of ilmenite beneficiation directly impacts resource utilization and economic viability, with three major challenges:

(1) Complexity of Mineral Association (Multi-Component Interference)

Common Associated Minerals:

- Strongly Magnetic Minerals: Magnetite (causing "over-absorption" in magnetic separation)

- Weakly Magnetic Minerals: Hematite, garnet (overlapping magnetic susceptibility with ilmenite)

- Non-Magnetic Minerals: Quartz, feldspar (reducing concentrate grade)

Special Cases: Panzhihua ores contain titanomagnetite (Fe₂TiO₄, >5%), making conventional magnetic separation ineffective.

(2) Low Recovery Rate of Fine Particles (-0.074 mm)

| Particle Size (mm) | Gravity Separation Recovery (%) | Magnetic Separation Recovery (%) |

| >0.15 | >80 | >75 |

| 0.074–0.15 | 60–70 | 50–65 |

| <0.074 | <30 | <40 |

Key Causes of Loss:

- High specific surface area of fine particles, easily washed away by water flow

- Weak magnetic particles receive insufficient magnetic force

(3) Composition Fluctuations Causing Process Instability

Impurity Effects:

- MgO > 2%(e.g., geikielite) degrades titanium dioxide product quality

- High CaO content(e.g., apatite) requires additional acid leaching

Mineralogical Texture Variations:

- Placer deposits: Mostly liberated grains

- Hard-rock deposits: Tight intergrowth with silicates (requires grinding to <0.045 mm)

2. Key Decision Matrix for Process Selection

(1) Ore Type Determines the Base Flow Sheet

| Ore Type | Recommended Process | Case Example |

| Beach Placers | Spiral Concentrator → Wet High-Intensity Magnetic Separation (WHIMS) → Electrostatic Separation | Murray Basin (Australia) |

| Hard Rock (Coarse) | Stage Grinding → Low-Intensity Magnetic Separation (LIMS) → High-Gradient Magnetic Separation (HGMS) | Lac Tio (Canada) |

| Hard Rock (Fine) | Ultrafine Grinding (<0.038 mm) → Froth Flotation | Panzhihua Microfine Processing Plant (China) |

| Weathered Deposits | Scrubbing & Desliming → Centrifugal Concentration | Wenchang Residual Deposit (China) |

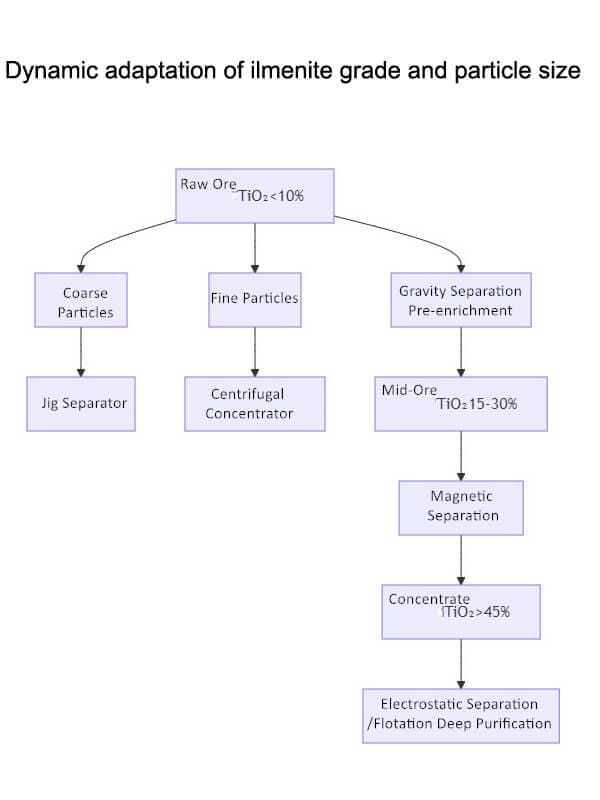

(2) Dynamic Adaptation to Grade and Particle Size

(3) Solutions for Specific Challenges

Magnetite Interference:

- Step 1: Low-intensity magnetic separation (0.2T) for iron removal

- Step 2: Medium-intensity separation (0.8T) for ilmenite recovery

Ultrafine Particle Recovery:

- Pulsating High-Gradient Magnetic Separation (SLon-2000): Recovers -0.02 mm particles at 65% efficiency

- Microbubble Flotation: Collector HY-3 at pH 5.5 improves selectivity

Ilmenite Beneficiation Process

Gravity separation

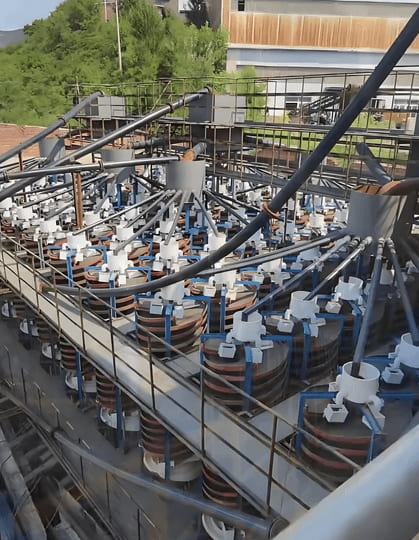

Utilizing ilmenite's high specific gravity (4.5–5.0), equipment such as shaking tables and spiral chutes removes light gangue minerals. This method is simple and energy-efficient, making it a common method for initial enrichment of ilmenite, particularly suitable for placer-type resources.

Magnetic separation

Ilmenite has moderate magnetic properties and can be effectively separated from weakly magnetic or non-magnetic minerals using high-intensity magnetic separators. For magmatic-type ilmenite, magnetic separation is a key step in improving concentrate grade and reducing iron impurities.

A combination of gravity separation and magnetic separation

In most mines, gravity separation and magnetic separation are often used in conjunction—gravity separation first removes light gangue, followed by magnetic separation for refining, improving overall recovery and concentrate quality.

Comparison of Major Ilmenite Beneficiation Processes

| Process Type | Applicable Ore Characteristics | Core Equipment | Advantages | Limitations | Typical Application Scenarios |

| Gravity Separation (Single) |

|

Spiral Chute/Shaking Table/Centrifugal Concentrator | No chemical pollution, low energy consumption | -0.074mm recovery rate <50% | Hainan Wenchang coastal sand mine |

| Magnetic Separation (Single) |

|

Wet High-Intensity Magnetic Separator (Slon Type) | Large processing capacity (100t/h) | Concentrate TiO₂ grade rarely exceeds 48% | Panzhihua titanomagnetite pre-enrichment |

| Gravity-Magnetic Separation (Combined) |

|

Spiral + High-Gradient Magnetic Separator Unit | Overall recovery rate increased by 15-25% | Process complexity, increasing investment by 30% | Vietnam Gai Chao rock mine project |

Conclusion

As a strategic resource, ilmenite not only plays a crucial role in the global titanium industry chain but also plays an increasingly important role in new energy and high-end manufacturing. Given the complex properties of the ore, a combination of gravity separation and magnetic separation remains the most universal and economical solution. For mining companies and equipment manufacturers, a deep understanding of ilmenite's resource characteristics and process challenges is crucial for seizing opportunities amidst fierce market competition and achieving efficient utilization and sustainable development.