JXSC Mining Machinery has a long history in mining area, and has acculated rich experience on small & medium scale mining and beneficiation. We work on offering equpment and EPC services for mine owner with small or medium scale processing plants, escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions.

From its tough beginning, the business that started in 1985 went to win the trust both home and board, with mineral processing machines sold to over 100 countries and regions( such as USA, Canada, Australia, South Korea, Japan, Mexico, Chile, Congo, South Africa).

Visit customer success cases to see what changes will our help of experience and technical expertise bring. May our experience in the various minerals like gold, silver, diamond, copper, tin, coltan, iron, chrome, titanium, etc. do you a favor in the increasing profit and reducing risks.

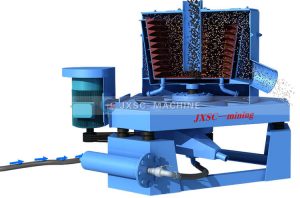

JXSC Mining & Beneficiation Equipment

Mineral Processing Solutions & Services

Get A Free Consultion Online, With Our Mining Experts

Mineral Processing Engineering Blog

Flotation: Pulp Depth & PH Value

The adjustment of flotation pulp includes pulp depth, PH value, etc., The depth and PH value will affect the flotation effect. In the flotation process, pH value has many effects on mineral flotation and is an important factor affecting flotation indexes. Following we will discuss the adjustment of pulp depth and PH value. Pulp Depth … Read more

Tin Ore Flotation Process

There are more than ten kinds of tin-bearing mineral deposits. At present, tin used in industry mainly comes from cassiterite. Because the density of cassiterite is relatively high (6.4~7.1g/cm3), the primary method of beneficiation of cassiterite is reselection. However, because cassiterite is brittle, it is simply siltified in nature and in the process of crushing, … Read more

Knelson Concentrator Gravity Separation of Polymetallic Ore Bearing Gold

Study on Knelson Concentrator Gravity Separation of a Polymetallic Ore Bearing Gold The major methods of recovering gold are gravity separation, gold flotation, cyanide. In fact, traditional gravity separators, such as jig machine, spiral chute, gold shaker table, have the shortages of low beneficiation ratio and low productivity. In addition, the flotation process is difficult … Read more

The Mineralogy of Tin

For tin mining equipment and beneficiation EPC solution, you can find in here Tin is a metal element, ordinary white tin is a low melting point metal with silver white luster. It is divalent or tetravalent in the compound and will not be oxidized by air at room temperature. In nature, tin is mainly composed … Read more

Grinding and grading equipment in beneficiation

Grinding and classification process Ball mill and rod mill process For beneficiation, one or two-stage grinding can economically grind the ore to any particle size required for beneficiation. The grinding of more than two stages is usually determined by the requirements of the selection of the stages. Compared with the two-stage process, the main advantages … Read more

How to Build A Manganese Ore Processing Plant

The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry tests. The magnetic separation process with 1 070 mm × 4 600 mm tank-type ore washing machine has a good effect. 1 Main equipment of manganese ore process plant The main manganese mining equipment … Read more